Low-Quality Cotton May Not Make Nice Shirt, Could Make Alternative to Plastic

By: Karen Michael

When cotton is abundant but the quality is low, farmers still need to sell the product.

Texas Tech University researchers are exploring ways to use cotton that may not be ideal for a shirt or jeans.

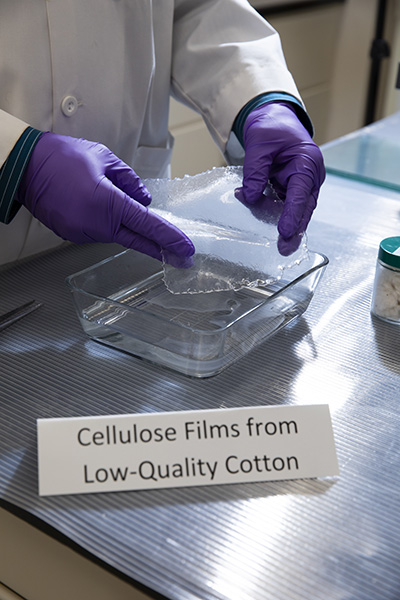

Noureddine Abidi is a professor in the Department of Plant and Soil Science and the director of the Fiber & Biopolymer Research Institute, or FBRI. One of the possible ways that he has found to make a profit from low-quality cotton is in mimicking another product entirely. Researchers at FBRI have found a way to make a gel from low-quality cotton that can be formed into a product very much like plastic.

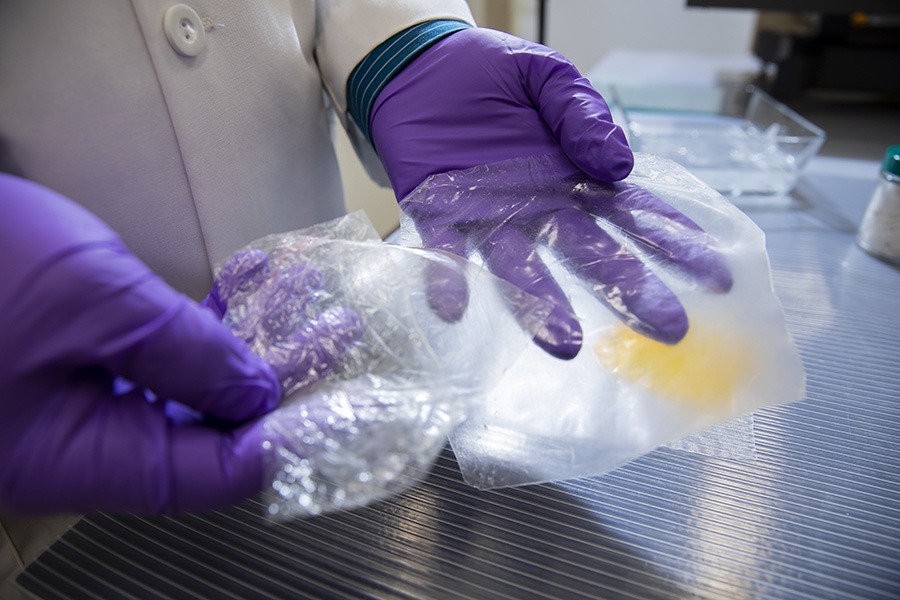

When handled, the smooth and pliable product looks and feels very much like the same plastic found in sandwich bags. It can also be made into thicker forms for other needs.

Normal plastic is a petroleum-based product. It does not decompose easily. But the benefit of using cotton for a similar purpose, such as the ubiquitous grocery bags overflowing from under the sink of almost every home, is that once that product is tossed in the trash and exposed to rain and soil bacteria, it will decompose.

“It is basically going from the soil to the soil,” Abidi said of that process.

The tricky part of using cellulose in cotton fibers to form a product is that it cannot simply be melted into the desired shape. Cotton fibers must be dissolved and molded in a gel form and film, because cotton does not melt.

Abidi said the new product was not developed as a way to make a new product out of cotton necessarily, but as a way to make a product from low-quality, or low-micronaire, cotton.

“We are not just going to tell cotton producers, don't worry about cotton quality, just make fiber,” Abidi said.

There is plenty of demand for high-quality cotton from textile mills in Asia, Abidi said. However, growing cotton can be impacted by mother nature, so when cotton producers harvest cotton that is less desirable for textile processing, they need a place to sell it.

“We are still going to find a market for that,” Abidi said. “Every year, we have a good amount of cotton that is discounted. That is really what we are looking for.”

The FBRI has been for many years a leader in interdisciplinary, collaborative research with different entities within and outside TTU. The FBRI labs provide valuable research and evaluation services to cotton breeders, researchers, producers, and seed companies. They also provide excellent opportunities for undergraduate and graduate students to perform their research projects on cotton.

The FBRI facility, located off East Loop 289 in Lubbock, tests every aspect of the cotton fibers, from seed cotton ginning, to processing, spinning, dyeing, and finishing.

“Everything is under one roof. We gin the cotton. We test for the quality. We spin, and then we form a small piece of textile product, either knitted or woven, and then we can test for the quality of that textile product. We can also do dyeing here, and we can also finish. Everything here is under one roof,” he said. “I think we are the only one in the world going all the way from the seed to the final product. FBRI is becoming the premier institute to do this kind of work on cotton.”

Discoveries

-

Address

Texas Tech University, 2500 Broadway, Box 41075 Lubbock, TX 79409 -

Phone

806.742.3905 -

Email

vpr.communications@ttu.edu