|

||||

| by Steve Estes | ||||

|

|

||||

Black

steel wrapped around the heels of one’s boots, overlaid with silver

markings that symbolize the heritage of both man and horse alike. The markings

are a signature of the hands that so long ago forged the steel and engraved

the silver. Black

steel wrapped around the heels of one’s boots, overlaid with silver

markings that symbolize the heritage of both man and horse alike. The markings

are a signature of the hands that so long ago forged the steel and engraved

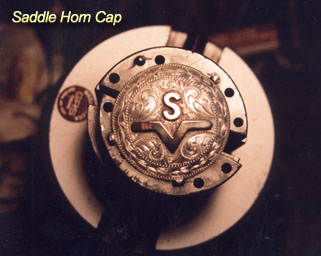

the silver.For years, spur makers have combined many cultures to create their own artistic style, which can be compared to artists who master their own unique style of painting. Roy Bowling, a 1998 animal science graduate of Texas Tech University, is one of the many spur makers of today, but what sets him apart from the rest is his strive for perfection. A Southeastern Kansas native, Bowling attended Fort Scott Community College in Fort Scott, Kansas on a rodeo scholarship. It was there when he got his first experience in spur making. Bowling traded a set of his own spurs to a friend who promised to build Bowling a new set and also give him a lesson on how to build spurs. "I thought it would be a great college job so I got a loan and jumped right in," Bowling said. Bowling then attended a bit and spur trade school in Idaho where he was able to learn building styles from all over the Southwest.  "There were many teachers at the school and they exchanged different ideas of style to us," Bowling said. There are two main styles of engraving when it comes to building spurs. There is a California style, which comes from old Spanish cultures. This involves the engraving of flower and scroll designs. The other is Texas style, involving the engravement of wheat stalk designs. Bowling said that the history behind the two styles really just involves the tools that were used in the past. Blacksmiths did Texas style engraving by placing their spurs in a vice. The wheat stalk is a rather straight object to draw, so it was used because the blacksmiths were unable to move the spurs while in the vice. Spanish spur makers placed their spurs on tree stumps while engraving; therefore, it was easier for them to roll the spurs around and draw the flower and scroll designs. Today, Bowling does his own engraving, which is what he enjoys most. "It gives me a chance to be creative," Bowling said.  Bowling

said that the basic styles of spurs haven’t changed much, but it is

the engraving and the markings that show a signature of the hands that built

them. Bowling

said that the basic styles of spurs haven’t changed much, but it is

the engraving and the markings that show a signature of the hands that built

them.Bowling often finds himself buying other spur maker’s products to help him come up with new ideas for his own. "I believe that everyone should buy other people’s products, it helps them build better spurs," Bowling said. It takes time for spur makers talent to develop. Bowling has been in the business for eight years and is currently building spurs as a full-time job. Bowling said that his family brought him to Lubbock. "I have family in Midland and by coming to Tech gave me a chance to be closer to them," Bowling said. Bowling’s grandparents met and both graduated from Tech before moving to the Midland area. After moving to Lubbock, Bowling and his wife Laura purchased a home and built a 20 by 40-foot shop. In addition to spurs, Bowling also builds bits, buckles and some jewelry. Bowling has also made buckles for the Texas Tech Mask Rider. Most days Bowling can be found in his shop building spurs, which he builds an average of 75 pairs per year.  On other days he can be found doing what he also loves, working with cattle and his horses. Bowling said that between spur making, cattle and horses, what he enjoys most of all is spending time with his wife and family. |

||||