|

|

It was late one afternoon

when I arrived at Buster’s Gin outside of Ropesville, Texas. I walked

into the office and was greeted by children chasing one another around

the office and eating their after school snack.

I

asked for Dan Taylor and was quickly directed to the back of the building

where I could hear someone on the phone laughing and joking. I

asked for Dan Taylor and was quickly directed to the back of the building

where I could hear someone on the phone laughing and joking.

It was Taylor. As

I stood by his office door patiently waiting my turn, he motioned for

me to come in and have a seat.

As I sat there, I

noticed plaque after plaque on the walls of his office. From the Lubbock

Chamber of Commerce to the State FFA Association, Taylor has received

awards from all over the state.

He continued with

his phone conversation laughing at times and then getting very serious,

telling the person on the other end how much he appreciated all he had

done for him and his family.

As he got off the

telephone, we took care of introductions and he asked if I would like

anything to drink. He then proceeded to ask me the usual questions: where

are you from, what is your major, how is school, etc.

I began to fire away

my questions, as he answered each one with a short, thoughtful answer.

Since

1947, Buster’s Gin has been serving the South Plains cotton industry.

Customers from an 80-mile radius bring in their cotton each year because

of the dedication and superior quality ginning that Dan Taylor provides. Since

1947, Buster’s Gin has been serving the South Plains cotton industry.

Customers from an 80-mile radius bring in their cotton each year because

of the dedication and superior quality ginning that Dan Taylor provides.

Dan Taylor has been

the backbone of Buster’s Gin since 1986. He has solicited nearly

all of the customers he has today and has turned the gin into one of the

most technologically advanced gins in the state.

Dan and Linda Taylor

are the owners and operators of Buster’s Gin and have been on the

South Plains since the 1960s when they both attended Texas Tech University.

“I had never

been to Lubbock until I came to Texas Tech,” Taylor says.

Taylor received his

bachelor’s degree in agricultural education in 1964. Upon graduation,

he began teaching at Lubbock-Cooper High School. He remained at Lubbock-Cooper

until 1975, until he was given an opportunity to work in the cotton industry.

In 1975, Taylor became

manager of the gin with the option to purchase part of the company. Buster’s

Gin was one of the only family operated gins left in the state at that

time and no family member wanted to take over the operation.

By 1986, Dan and

Linda were owners of the gin and eager to make it the best gin in the

state. Taylor quickly updated the gin with the latest technology and equipment.

Taylor has built an educational expansion on his gin to allow civic groups

and local schools and universities to experience the process of ginning

cotton.

The expansion includes

a room overlooking the entire gin so groups can see all of the equipment

in action. It also includes a “mini-museum” with antique gin

equipment.

The greatest satisfaction

from the educational expansion is that Taylor gets to incorporate an educational

outlook on the ginning process.

“By having groups

come out and tour the gin, I still get to use the skills and techniques

I learned when I was teaching,” Taylor said.

The museum includes

a ledger containing the first records of the gin and some equipment from

Lukenbach, Texas. Taylor has collected memorabilia over the years and

finally decided to put it in a place for everyone to see.

“I’ve

had most of this stuff for years and thought that I should let everybody

else get as much enjoyment out of it as I do,” Taylor said.

While taking a tour

through the gin, I asked Taylor where he thought agriculture is headed.

He smiled and laughed, and then became serious.

“There are still

opportunities in agriculture, we just have to work hard to find and make

the best of them. At this point, there must be a source of outside income

for the agriculturist. Insurance rates are going up and it is affecting

every consumer,” Taylor said.

He was also quick

to add that he was probably not the best person to ask this question to,

but was willing to give his opinion.

Taylor eagerly showed me every piece of equipment in the gin. From the

switchboard that runs the entire gin, to the trucks that haul the cotton

to the gin, I got to see every aspect of the operation.

Taylor had the computer

that runs the gin specially designed. It is run with a touch screen, and

monitors every piece of equipment in the gin. With the addition of this

technology, it has helped to increase efficiency throughout the gin.

After the ginning

season is over, every piece of equipment in the gin is physically cleaned.

This cuts down on mechanical problems and prolongs the life of the machine.

With a $2 million press, maintenance and preservation are valuable traits.

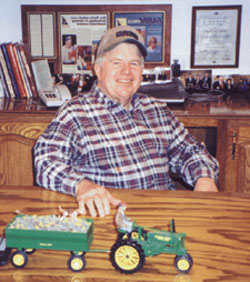

Aside from running the gin, Taylor also collects and restores John Deere

tractors. He has had this hobby for about 10 years and has a very impressive

collection.

He took me to see

his collection and I was amazed. He has two barns full of restored tractors

and equipment. How he finds time to have such an extensive hobby will

always astonish me. Taylor said he hopes to one day take some of his tractors

to competitions, providing he can find the time to be away from his busy

schedule at the gin.

Dan and Linda have

three children: DeLinda, Darrell and Davon. All three have degrees in

agriculture, with DeLinda and Darrell being Texas Tech Alumni. Davon graduated

from Texas A & M University.

When talking about

his family, Taylor is very humble and offers information of what his children

mean to him and how proud he is of them as individuals and their achievements.

One thing that Taylor

cannot get enough of, is the competitiveness of the ginning industry.

“That’s

why I like ginning,” Taylor says. “The competitiveness is fun.”

He says that to be

successful and competitive with other gins, volume is necessary. Taylor

says the most drastic thing that changed the harvest of cotton and the

ginning process was the invention of the module builder.

A module is a temporary

bale of cotton. After the cotton has been compacted into a module by the

machine, it is covered with a tarp to stay fresh and ready to gin.

It was developed

to solve the problem that resulted after harvest. Long waits to unload

at the gin stalled harvest until the trucks could return to the fields.

Taylor says that

genetics, chemicals and fertility have also improved the cotton industry.

These factors have helped to produce a better final product.

He has ginned cotton

by hand, with two-row equipment, four-row equipment and eight-row equipment.

The equipment used now is automatic and very consistent.

The Taylors have

also produced a video called “From Field to Finished Bale.”

It describes the process cotton must go through from starting in the field

to finishing in the gin. It is the only video of its type and is 13 minutes

long.

Nothing

was disrupted to make this video. It was done by a professional and no

shots were set up, no machines were stopped and employees continued their

jobs. Over 48 hours of video was shot to make the video. The Taylors fulfill

requests for the video from all over the nation. Nothing

was disrupted to make this video. It was done by a professional and no

shots were set up, no machines were stopped and employees continued their

jobs. Over 48 hours of video was shot to make the video. The Taylors fulfill

requests for the video from all over the nation.

Every fall, the Taylors host a barbecue for their customers to show their

appreciation. All customers are invited to enjoy a meal and visit with

each other. Videos are continuously played and photo albums are laid out

for customers to observe.

In the future, Taylor hopes to continue with his collection of antique

gin equipment and hopes to start a display showing all the different products

made from cotton.

“If I could

go back to teaching, I would,” Taylor says. “Luckily with the

gin and my educational tours, I get the best of both worlds.”

|

|