Color-changing Film Could Provide Solutions to Counterfeiting and More

By: Karen Michael

Imagine a film that could be used for anti-counterfeiting, security, or optical color filtering by responding to humidity by turning colors or perhaps by showing a colored pattern.

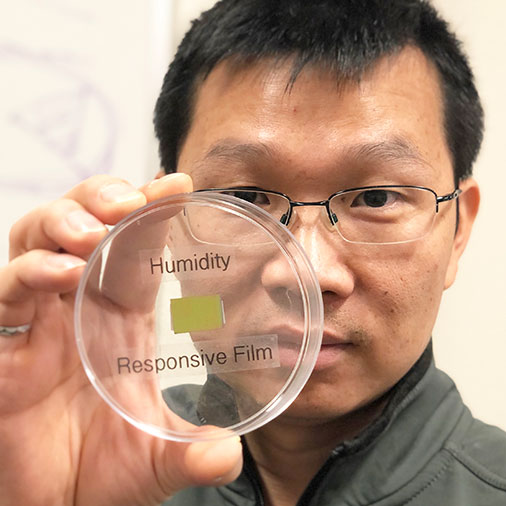

Wei Li, an assistant professor in Texas Tech University's Department of Chemical Engineering, had his team's research into the development of that film, a photopatternable nanolayered polymeric film, published in August by Advanced Functional Materials.

The film responds to a change in humidity by expanding and changing its color. Li said this is because the film has a structural color rather than a pigmented color.

Some of the earliest films developed by Li's team feature the Texas Tech Double T logo. When the film is removed from a box and breathed on, the Double T appears. Li said this works even in areas with a different level of humidity. For instance, that Double T will appear even on the most humid days in a state like Alabama, just as it does in the normally dry climate of Lubbock, Texas. The starting color of the film might be different depending on the humidity level in the area, though.

Someday, the film could be possibly used in currency, Li said. Instead of looking at a dollar bill under UV lights, he said it might be possible to just breathe on an embedded film.

Li said the film could also be used in wearable electronics in the future, or in any application that requires some smart surface. It could also be used in artworks, he said, adding that artists could apply steam to their work to change its design or message.

"I think it's a very interesting, very neat material," Li said. "Its responsiveness is very unique."

The film is also fairly inexpensive. Normally, Li said, structural color surfaces are created with sophisticated techniques used in nanophotonics, which he said can be expensive.

"What we use here is just a polymer film. The components of this are really just a very bio-friendly, naturally abundant polymer. So the cost is not that much," Li said. It is created through a process called layer-by-layer assembly, a thin film fabrication technique.

Because the film does not have to be made in a sterile laboratory, he said it could one day be inexpensive to manufacture it.

"We have to optimize the process to make it more manufacturable," he said.

Li said the next step for researchers looking at this film is figuring out how to apply it to another surface. In its current state, the film is mounted on a silicone surface which is rigid and limits the applications of the film.

"Next step, we need to see if it can go onto something more flexible," Li said.

Texas Tech researchers also want to make the film able to record any changes in temperature or humidity. That could be helpful if it were used in packaging of vaccines or medicines that must be held at a certain temperature during storage or transportation. A tag that could tell you about a history of temperature or humidity changes could help medical workers to be confident about a drug's efficacy, Li said.

Li received new faculty startup funds from Texas Tech and Spark Funds from the Global Laboratory for Energy Asset Management and Manufacturing, or GLEAMM. This work is also collaborated with Dr. Qiaoqiang Gan, an associate professor from Department of Electrical Engineering, University at Buffalo.

Discoveries

-

Address

Texas Tech University, 2500 Broadway, Box 41075 Lubbock, TX 79409 -

Phone

806.742.3905 -

Email

vpr.communications@ttu.edu