Project 0-1331

Use of Glass Cullet in Roadway Construction

Abstract

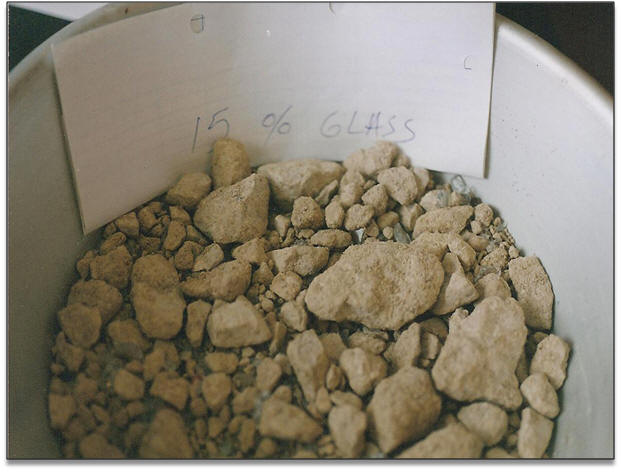

The purpose of this study is to develop specifications for using glass cullet in roadway construction. Glass cutlet results from collecting and crushing post consumer glass containers. Using glass cullet in roadway construction avoids expensive sorting to prevent color contamination and presents an opportunity to use glass cutlet as a construction aggregate and reduce landfill requirements. A number of other states and organizations have investigated the use of glass cullet in various aspects of construction. Specifications for using glass cullet for roadway construction in the State of Texas were developed in three phases: (1) Literature Review and Identification of Available Sources and Suppliers; (2) Laboratory Testing; and (3) Specification Development. An earlier report presented findings from Phase I, literature review and identification of available sources and suppliers. This report covers Phase II, Laboratory Testing and Phase Ill, Specification Development. Findings from the literature review revealed a number of states have investigated the use of glass cutlet in roadway construction and several have developed applicable specifications. An extensive study was performed by the Clean Washington Center and their report served as a primary source of information for the study reported herein. Specifications for the other states were used as guidelines for developing specifications for the State of Texas. Only a limited number of suppliers were located in Texas. Samples from Texas suppliers were evaluated in limited laboratory testing and the samples obtained from Texas suppliers were found to be free of lead, a potentially toxic substance. No hazardous materials were found in the samples. Orginally, a life cycle cost analysis was planned for glass cullet as an alternative to conventional construction aggregate. However, any such life cycle cost analysis was deemed premature because the glass recycling industry is in the early stages of development. Glass cullet received from the glass cutlet supplier contained less than one percent debris. Debris consisted of paper, plastic and cork. Debris levels were vaned from 0 percent to 1 percent by weight of glass cullet. Furthermore, the glass cullet with various debris levels was blended with crushed limestone at various mix proportions. Laboratory testing included triaxial, permeability, compaction, wet ball mill, gradation and stripping tests. Draft specifications were prepared for embankments, base course backfill, drainage materials and detour construction. Both the Houston District and the Abilene District were identified as possible locations for a demonstration project. The primary Texas supplier of glass cutlet is located in the Houston District. A supply of waste glass is available in the Abilene District, but requires crushing into cutlet.

Project PI:

Phillip T. Nash, P.E.

Project Researchers:

Center for Multidisciplinary Research in Transportation (TechMRT)

-

Address

Texas Tech University, Box 41023, Lubbock, TX 79409-1023 -

Phone

806.742.3523 -

Email

techmrt.outreach@ttu.edu