Nanorheology

Paul O'Connell

Stephen Hutcheson

Shanhong Xu

Taskin Karim

Jinhua Wang

Rheological Measurements of the Thermoviscoelastic Response of Ultrathin Polymer Films

In recent years, considerable effort has been put into understanding the change in the behavior of polymeric materials when they are reduced to the nanometer size scale. In particular it has generally been observed that the material at the nano-scale shows a reduced glass transition temperature (Tg), though it should be noted that this remains a controversial area of research with often-conflicting results on the presence and magnitude of such changes. The aim of my current research is to develop and apply a new nanorheological measurement method that allows the determination of the viscoelastic response of thin films in which the film thickness and lateral constraints can be varied systematically. The approach we have taken is to scale down the mesosopic bubble inflation biaxial test method such that polymer films of nanometer thickness can be tested.

*O'Connell P.A. and McKenna G.B., Science, Vol. 307, No. 5716, 1760-1763 (2005)

Our results on the creep compliance of a polystyrene and polycarbonate show reductions in Tg of approximately 60 °C down to a thickness of 13 nm and some 80 °C down to a thickness of 9 nm respectively. Interestingly, poly(vinyl acetate) (PVAc) shows no significant change (< 3 °C) in the Tg down to a film thickness of 23 nm suggesting the reduction in Tg as the film thickness is reduced is not a universal phenomenon. The results do show, however, surprising stiffening in the rubbery response regime, with the material stiffness scaling as approximately the square of the thickness. This is true for all three materials.

Future work will extend the measurements to holes of varying diameter and shapes to vary the confinement conditions.

Funding

- National Science Foundation

- U.S Army Research Office

Rheological Property Determination at Surfaces and at the Nanoscale by Nano and Microsphere Embedding

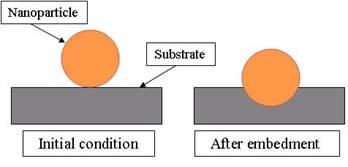

We are performing nanorheological studies using embedment of micro and nanospheres to study the mechanical properties of polymeric surfaces. We are performing experiments with nanospheres of different surface energies and radii to determine if there is a size effect (study of nanoheterogeneity of polymeric surfaces). The experiments will be accompanied by finite element simulations of embedding spheres.

Funding: National Science Foundation

Instrumentation

I am involved in the evaluation and comparison of a Sensotec strain gauge based and 2KFRT transducers in the ARES Rheometer.

Funding: John R.Bradford endowment at TTU

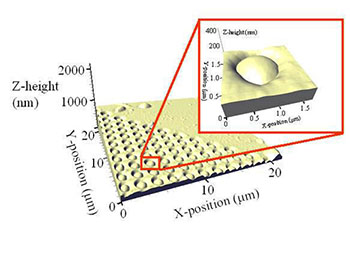

Distribution of the Surface Mechanical Properties in Nanocomposites by Spontaneous Embedment of Submicron Particles

There is considerable interest in the distribution of material properties in heterogeneous materials such as composites. Here, we are examining one nanocomposite system using a novel particle embedment method that allows the determination of the spatial distribution of the surface mechanical properties of heterogeneous materials. We use Universal SPM atomic force microscopy (AFM) from Ambios Technology and elastic models of contact mechanics to evaluate the modulus of the surface.

Schematic of Particle Embedment

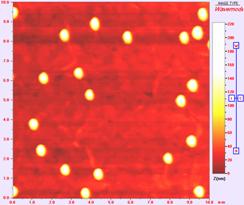

AFM Images and the Height Distribution of Particles

Our initial result shows that the calculated modulus values were found to be significantly lower than expected from macroscopic measurements on the epoxy nanocomposite.

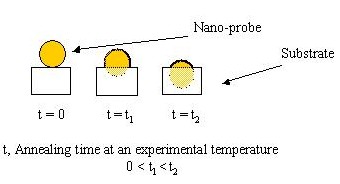

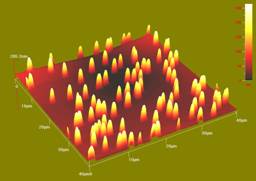

Determination of the Elastic Properties of Spin Coated Lipid Multibilayer Films by Embedment of Sub-micro Sized Particles

In recent years, much work has focused on the behavior of materials at the micro-, nanometer size scales. Teichroeb and Forrest[1] proposed a novel nano-particle embedment technique to study the properties of polymer surfaces. The purpose of the present work is to use this method to examine the mechanical properties of lipid multibilayer films. The standard JKR model[2] relates the shear moduli of the film to the embedment depth of the particle into the surface. In our experiments, particle embedment depth can be obtained by atomic force microscopy (AFM). This is used to obtain moduli of the lipid multibylayer films.

AFM image of 200 nm polystyrene particles dispersed on a 1,2-dipalmitoyl-sn-glycero-3-phosphatidylcholine (DPPC) multibylayer film.

References

J. H. Teichroeb and J. A. Forrest, "Direct Imaging of Nanoparticle Embedding to Probe Viscoelasticity of Polymer Surfaces", Phys. Rev. Lett., 91, 016104(1-4) (2003).

K. L. Johnson, K. Kendall and A. D. Roberts, "Surface Energy and the Contact of Elastic Solids", Proc. R. Soc. Lond. A, 324, 301-313 (1971).

Funding

- National Science Foundation

- John R.Bradford endowment at TTU

Viscoelastic Properties of Ultrathin Polymer Films on a Liquid Substrate

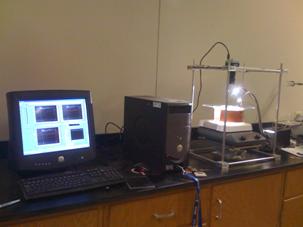

There is considerable interest in the behavior of polymer films of nonometer thickness. In particular, the mechanical response has been investigated in our lab using a novel bubble inflation method to obtain the creep response for films as thin as 10nm.[1] Yet the results of this method have yet to be replicated by other techniques.[2] The purpose of the present work is to investigate the reasons for the different results between the bubble inflation measurement and the liquid dewetting method of Bodiguel and Fretigny. To this end we have constructed a similar device to that of Bodiguel and Fretigny and are in the process of beginning measurement to replicate their results on polystyrene. Efforts will be made to compare bubble inflation results directly with those of the thin film dewetting experiment.

The picture of the thin film dewetting device

References

O' Connell P. A. and McKenna G. B., "Rheological Measurements of the Thermoviscoelastic Response of Ultrathin Polymer Films", Science, 307, 1760-1763 (2005).

H. Bodiguel and C. Fretigny, "Viscoelastic Dewetting of a Polymer Film on a Liquid Substrate," Eur.Phys. J. E ., 19, 185-193 (2006).

Mechanical Properties of PETN Crystal

Our objective is to determine the mechanical properties of PETN crystals at the nanoscale by using the AFM for either direct nanoindentation or microparticle embedment methods. Currently, our research has focused on establishing temperature and impurity effects. Figure 1 shows an AFM image of a Zn-doped PETN crystal.

Figure 1. The three-dimensional image of Zn-doped PETN crystal

Instrumentation: Atomic Force Microscopy

Polymers and Condensed Matter Physics Group

-

Address

P.O. Box 43121, Lubbock, TX 79409−3121 -

Phone

806.742.3553 -

Email

che@ttu.edu