Exposure Occurs During Use of Inoperable Fume Hood

September 2023

What happened?

During routine laboratory work, a student was exposed to hydrochloric acid fumes. A student was working inside of a chemical fume hood to transfer the hydrochloric acid when the pipet tip fell off the pipet being used to transfer from the container. The acid began to release fumes as contaminants on the pipet mixed into the acid.

Lab personnel quickly evacuated the room when they noticed the reaction and that the fume hood was not functioning properly to remove the vapors.

What caused the incident?

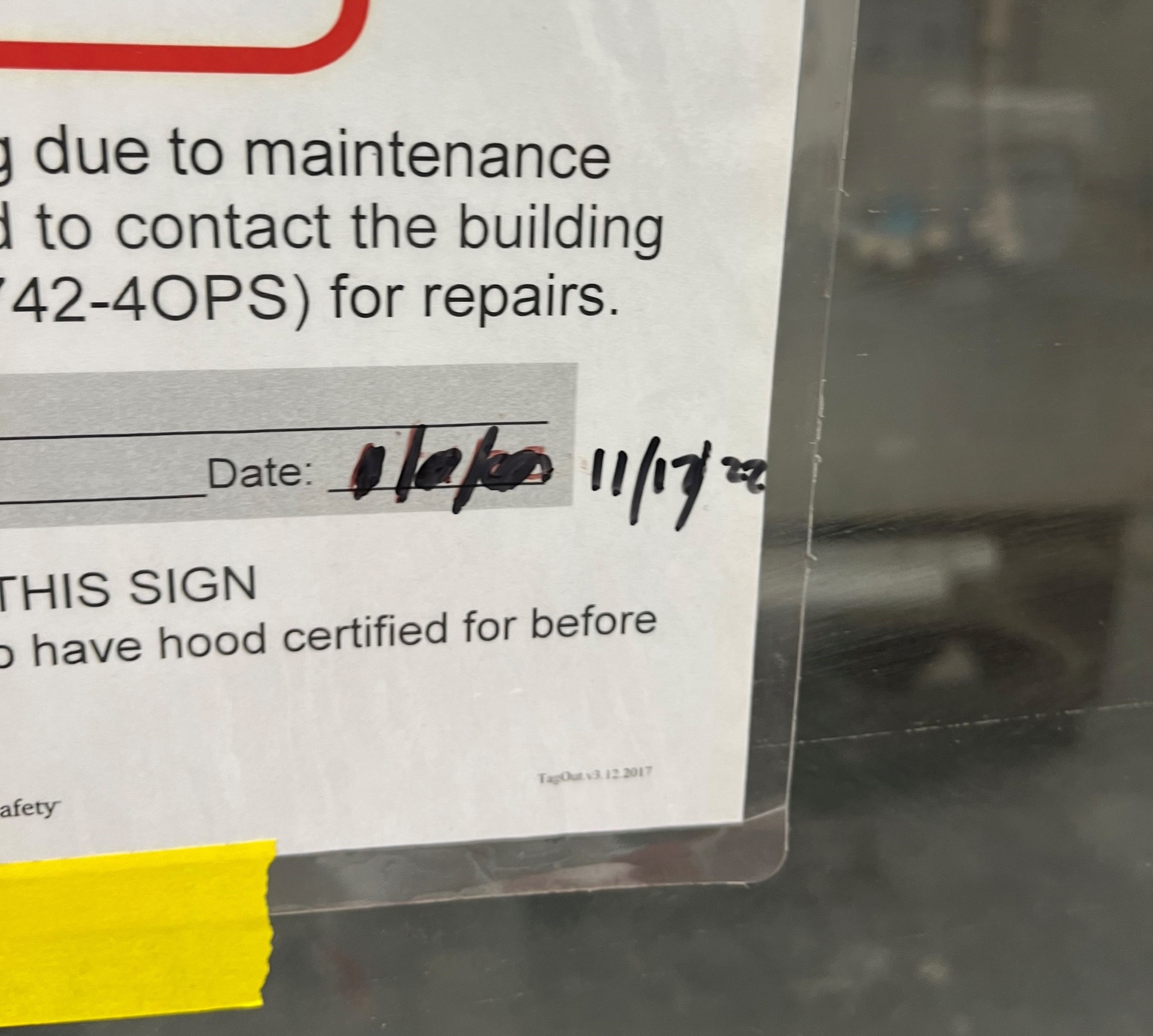

The fume hood had been marked inoperable in November of 2022. Perhaps time constraints often placed on research projects encouraged dismissal of the warning sign, especially since the repair time had been so lengthy.

Failure to adhere to posted signage indicating the inoperable fume hood lead to an exposure of hydrochloric acid. If a fume hood is functioning properly, dusts and fumes are kept within the fume hood and exhausted outside of the building.

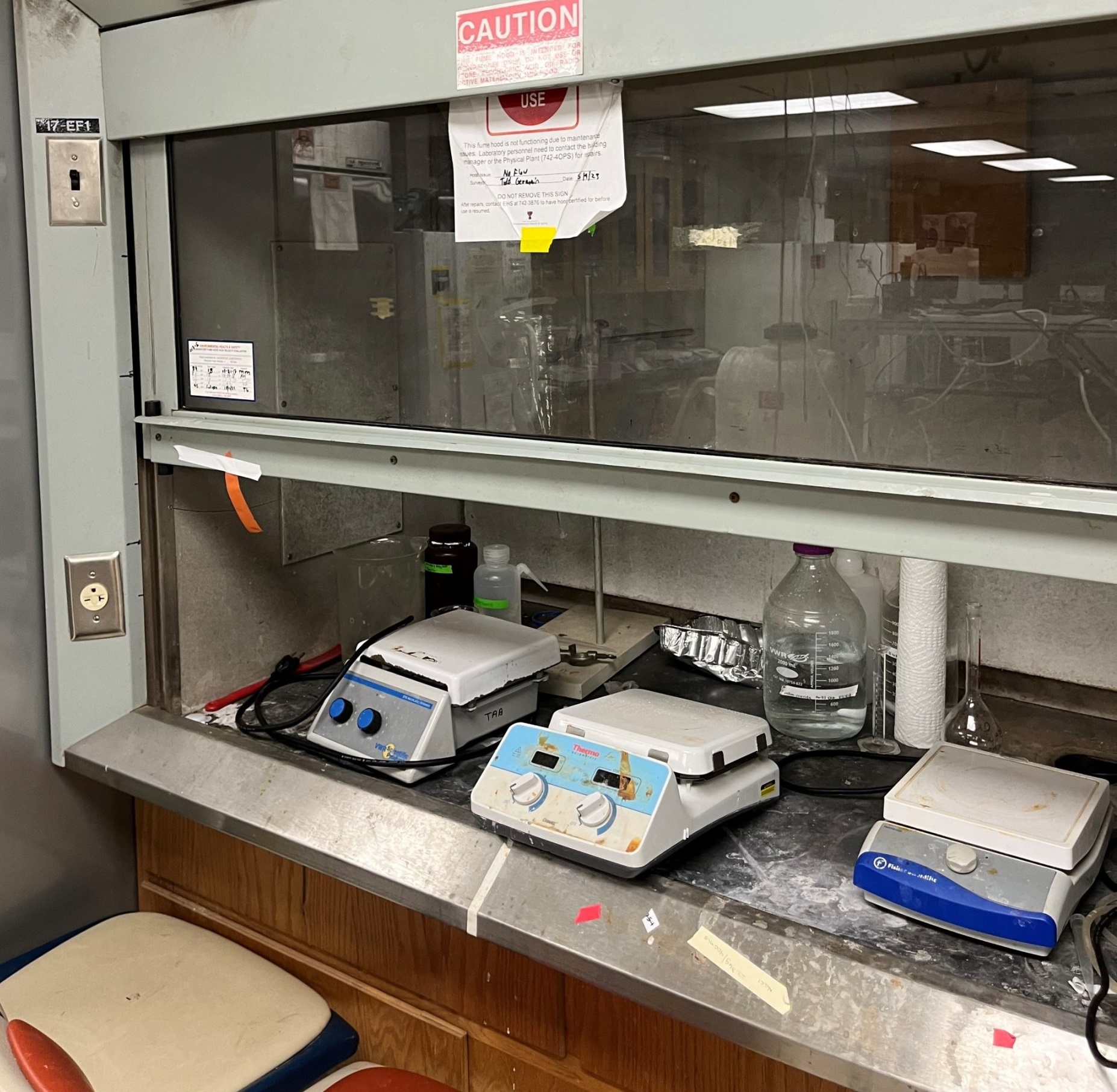

A second fume hood in the space had been marked inoperable during safety surveys in 2023 in the buidling. During the exposure investigation, both inoperable fume hoods appeared to be in use.

Note that all equipment should be placed at least six inches inside the face of the hood. The placement of items too close to the hood face may have excerbated the exposure.

How can we prevent future incidences or minimize injuries?

- Always pay attention to posted signage in your work area and in other areas on campus. Signage is there to indicate a warning to you or make you aware of a characteristic of a space or item.

- Ensure proper fume hood usage, including checking that fume hoods are flowing properly prior to beginning work. A visual flow indicator, such as a strip of paper towel or flagging tape, is required on all fume hoods. The indicator should be gently pulled into the face of the hood sash once the fume hood is turned on.

- When safety equipment or engineering controls are marked as inoperable during EHS surveys, lab personnel are responsible for submitting the Work Order to have it repaired. Sometimes repairs can take a long time if parts need to be ordered, especially for older fume hood models.

- EHS has updated the Fume Hood Tagout Sign to make it more visible that EHS must re-certify fume hoods after repairs are complete.

Environmental Health & Safety

-

Address

Texas Tech University, 407 Flint Ave, Lubbock, TX 79409 (Mail Stop 1090) -

Phone

806.742.3876 -

Email

safety@ttu.edu