Research

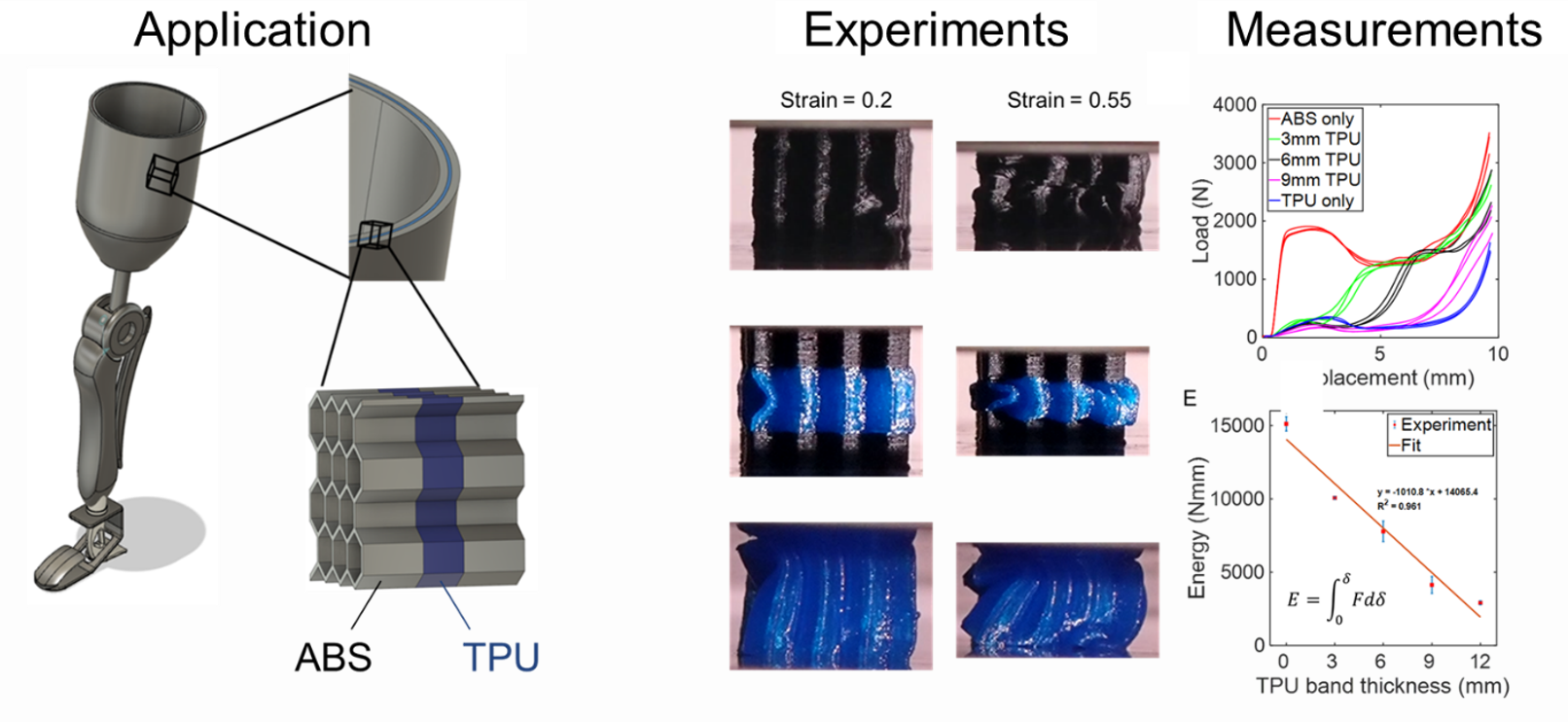

Multi-material lattice mechanics

Complex lattice structures are enabled by 3D printing and have a high mechanical efficiency for applications such as prosthetics. The figure below demonstrates our approach for fabricating multi-material lattices with stiff and flexible materials to design leg prosthetics with personalized mechanics for energy absorption.

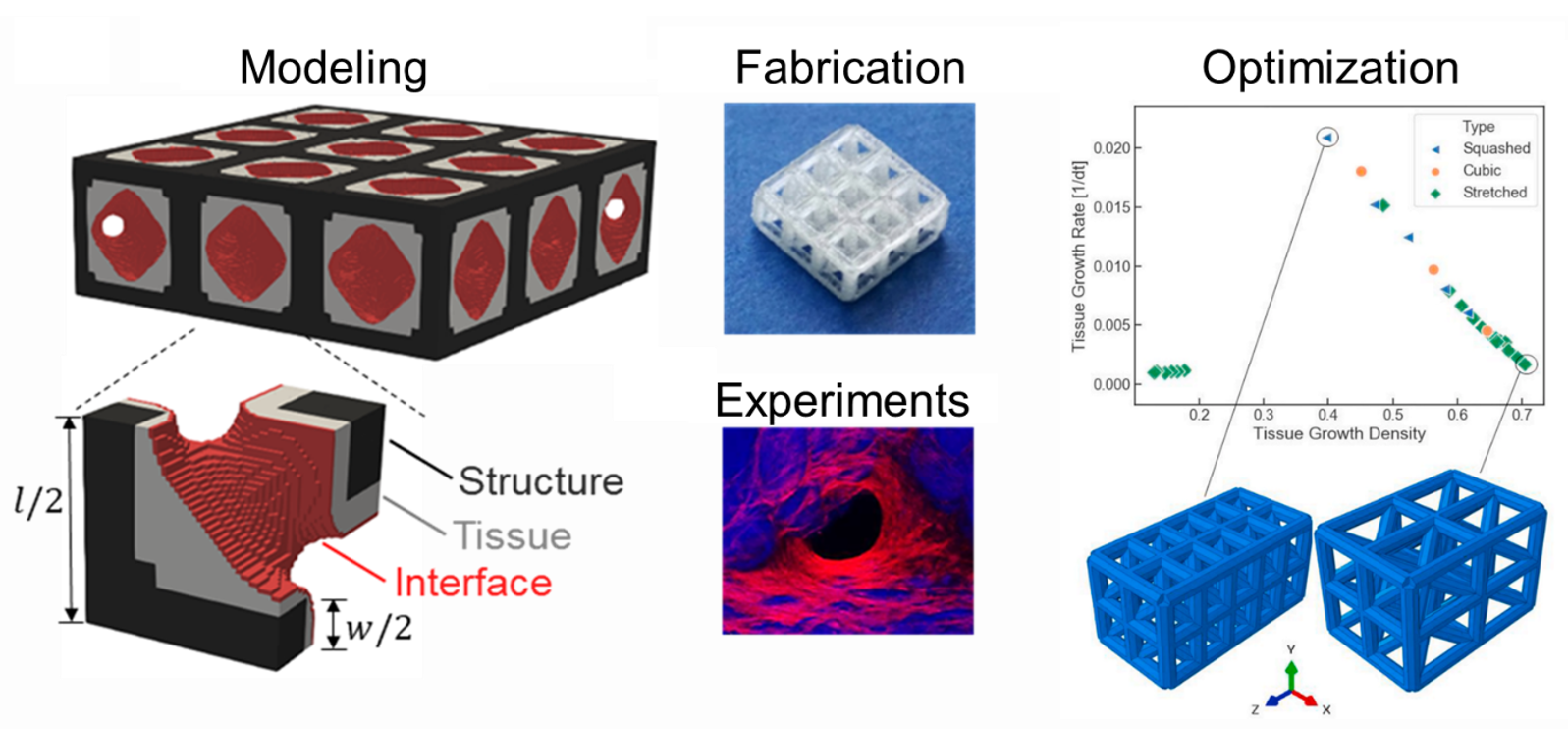

Computational tissue scaffold design

3D printing enables the design of tissue scaffolds that mimic bone's structure and mechanics to encourage bone regeneration and fusion. The following figure highlights our computational modeling approach for predicting tissue growth according to experiments, followed by fabrication of optimized scaffolds.

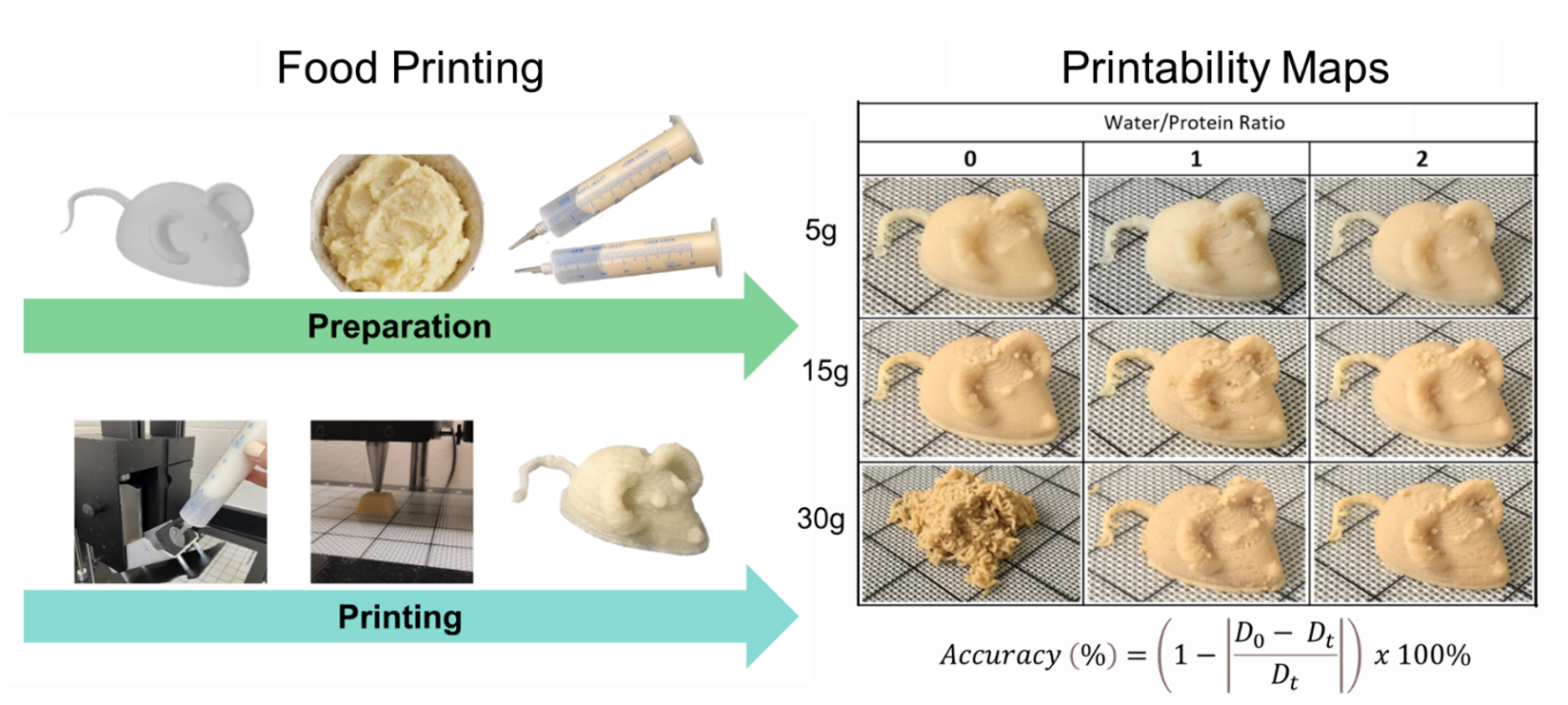

Personalized food fabrication

Food printing enables the creation of personalized meals with tailored taste, nutrition, and sensory appeal. The figure below demonstrates our process for printing foods via extrusion based on customized designs; printability maps demonstrate how different combinations of water and pea protein affect print fidelity.

Egan M3D Design Lab

-

Address

133A, Mechanical Engineering (North), Texas Tech University, 2500 Broadway, Lubbock, TX 79409 -

Phone

806.834.4887 -

Email

paul.egan@ttu.edu