Machine Learning for Quality Control

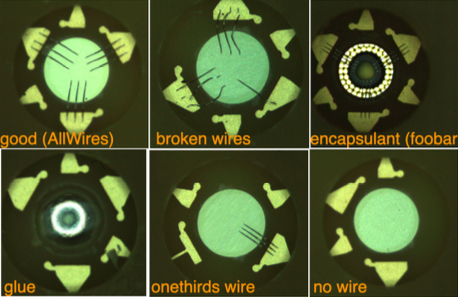

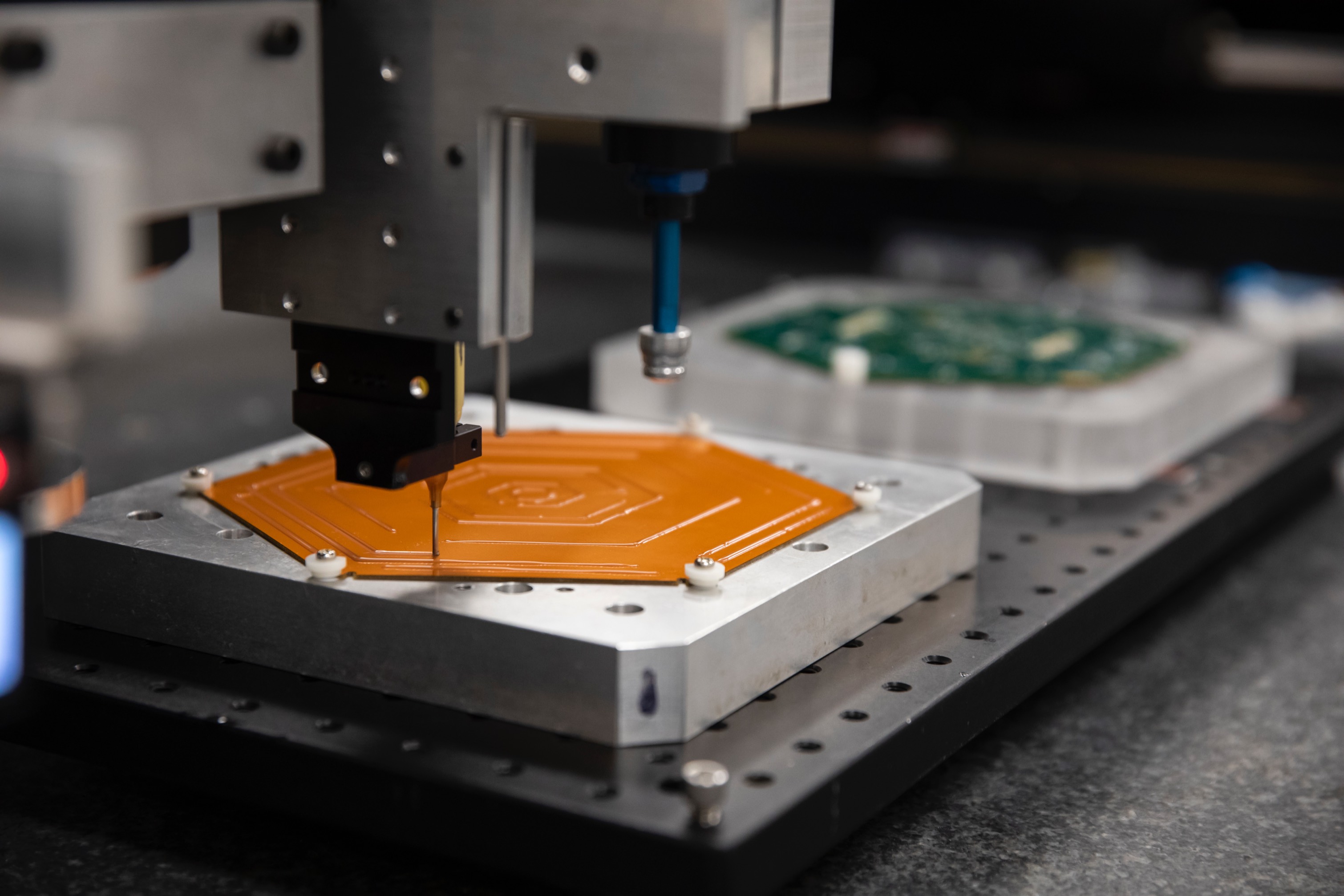

The wire-bond between the silicon sensor and the circuit board is the primary mode to collect the signal in a silicon detector. Hence, the clean and unbroken bond is one of the vital demands in the silicon module during the construction. Each of these bond holes needs to be inspected at least three times during the assembly i.e., before and after wire-bonding, and after encapsulation. Depending on the size of the detector, the number of the holes to be quality checked are at the order of million. The small dimension of the bond holes and the thickness of wires poses additional challenge in quality control. As manually checking each hole would be cumbersome and prone to human errors, we have been exploring and testing the deep learning-based computer vision to automate this quality control (QC). In particular, the image classification technique with the convolutional neural networks (CNN) has been utilized to identify the quality of the bond hole. In addition, we have been implementing the transfer learning and image segmentation techniques in this classification task. Can we transfer this learning outcome to other projects as well? This is one of the goals of our feasibility study.

Advanced Particle Detector Laboratory

-

Address

TTU Advanced Particle Detector Lab, 1204 S Gilbert Dr, Building 557 Lubbock, TX 79416-2104 -

Phone

806.790.7444 -

Email

sonaina.undleeb@ttu.edu