Bioprinting and Biofabrication Laboratory

Dr. Changxue Xu’s Bioprinting and Biofabrication Laboratory is located in 206 of the Department of Industrial, Manufacturing & Systems Engineering at Texas Tech University (TTU). It occupies approximately 1,000 square feet. Our research interests are:

- 3D bioprinting and biofabrication of tissue and organ models

- Multi-cellular tumor microenvironment

- Cancer cell migration and invasion

- Cell patterning and distribution

- Cell printing and cell encapsulation

- Cell-biomaterial interaction

- Organs-on-chips

- Additive manufacturing of functional materials

RESEARCH PROJECTS:

1. Cell Sedimentation and Aggregation in 3D Inkjet Printing

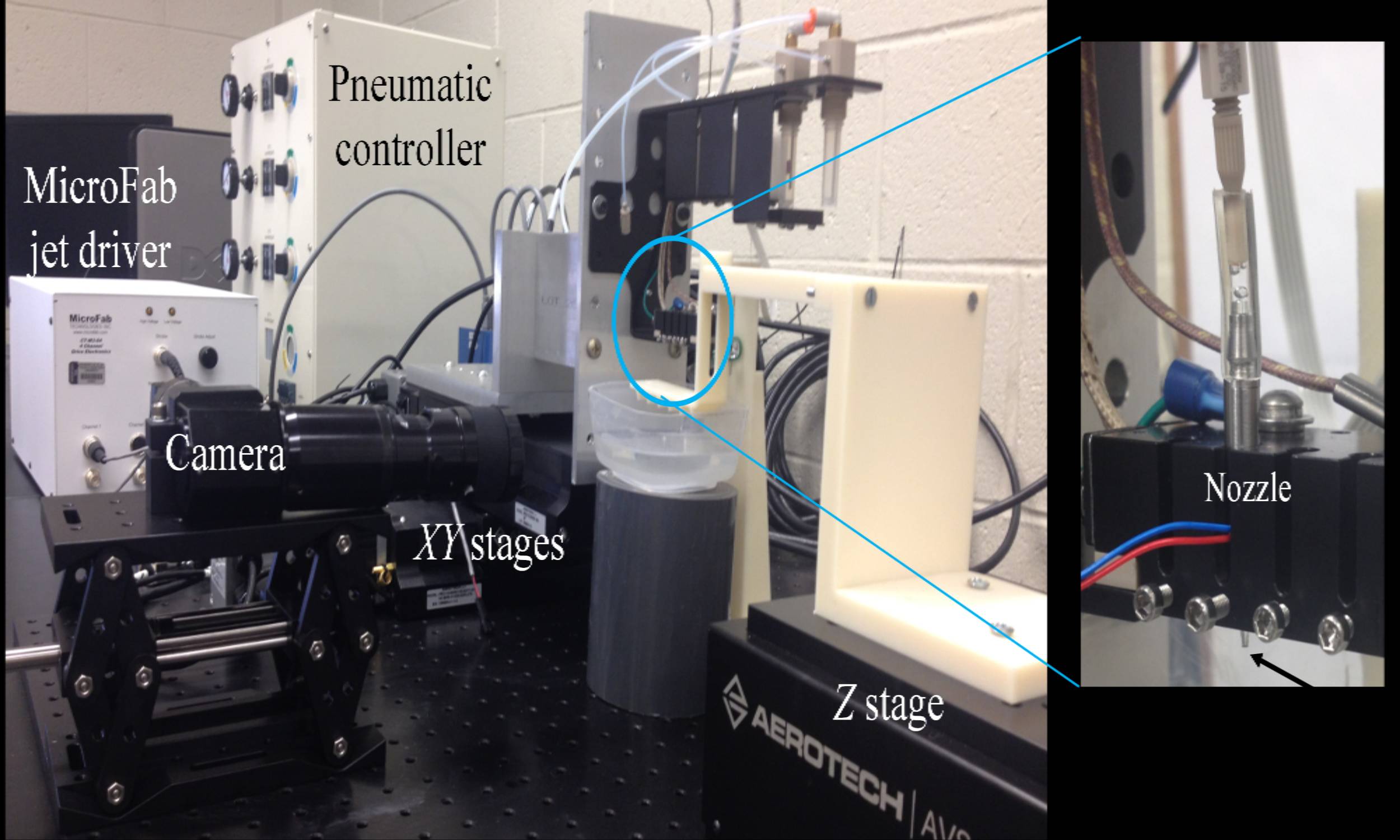

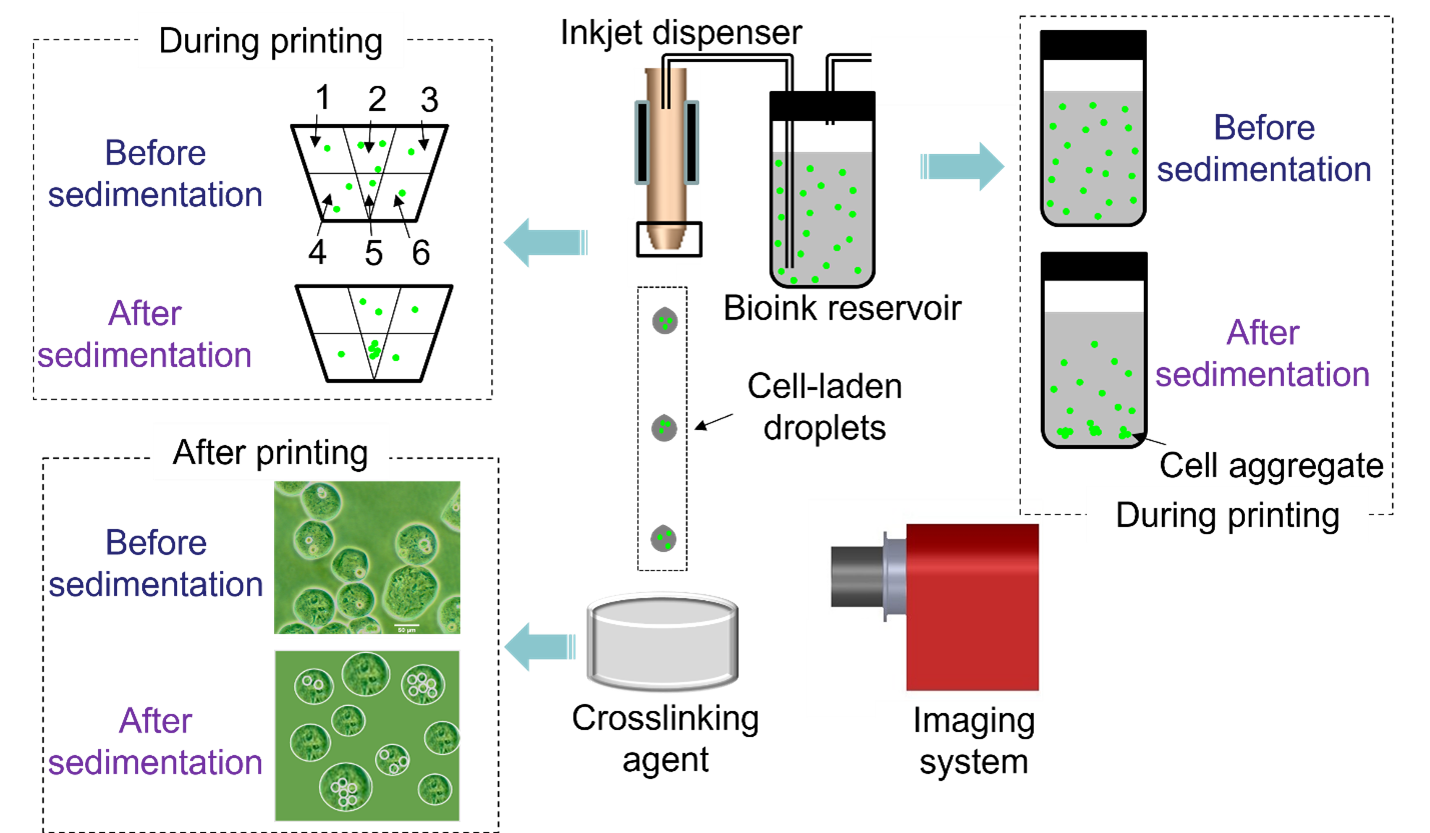

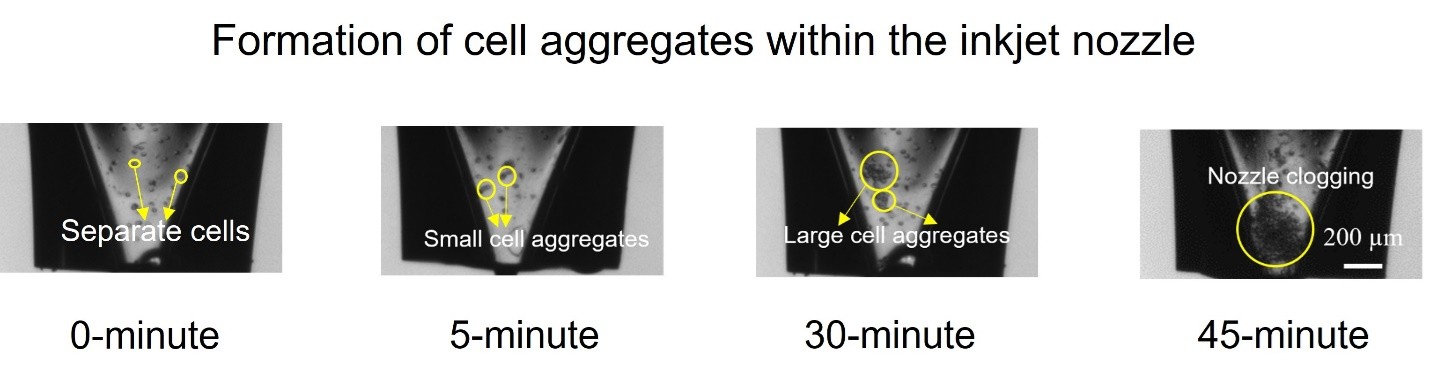

The 3D inkjet-based bioprinting system is composed of four key subsystems: motorized XY stages attached with a computer-controlled nozzle dispenser, a motorized Z stage attached with a Z-shaped platform where cell-laden droplets are deposited, a container with the calcium chloride solution inside, and an imaging system to visualize the droplet formation process during direct writing. The research project is “Understanding the Printing Dynamics during Inkjetting of Cell-Laden Bioink for 3D Biomanufacturing Applications” funded by NSF. During inkjet-based bioprinting, living cells adhere with each other to form cell aggregates, resulting in nozzle clogging and unplanned droplets. This project studies the mechanism of living cell aggregation, and the effects of cell aggregates on the droplet formation process during inkjet printing. The research outcomes will significantly improve inkjet printing reliability in regeneration of 3D functional tissues and organs.

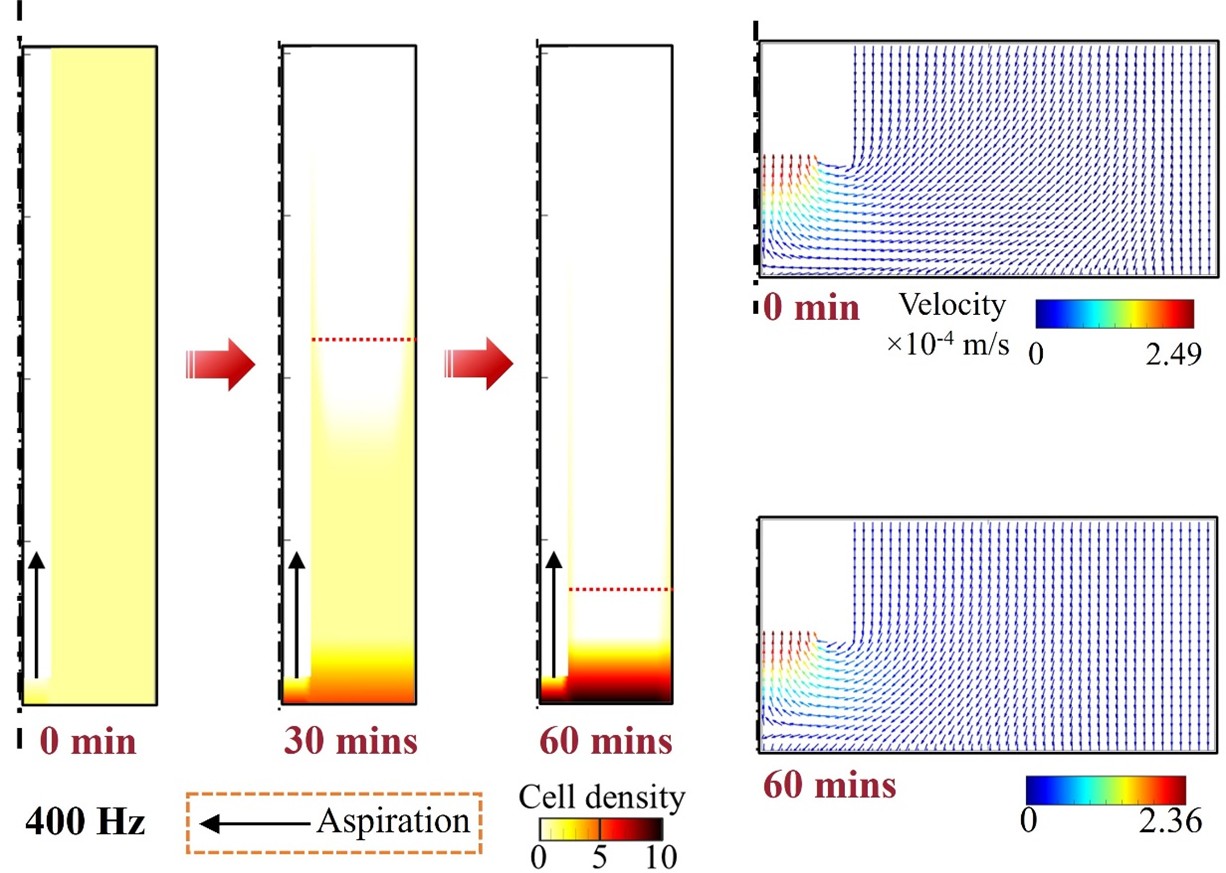

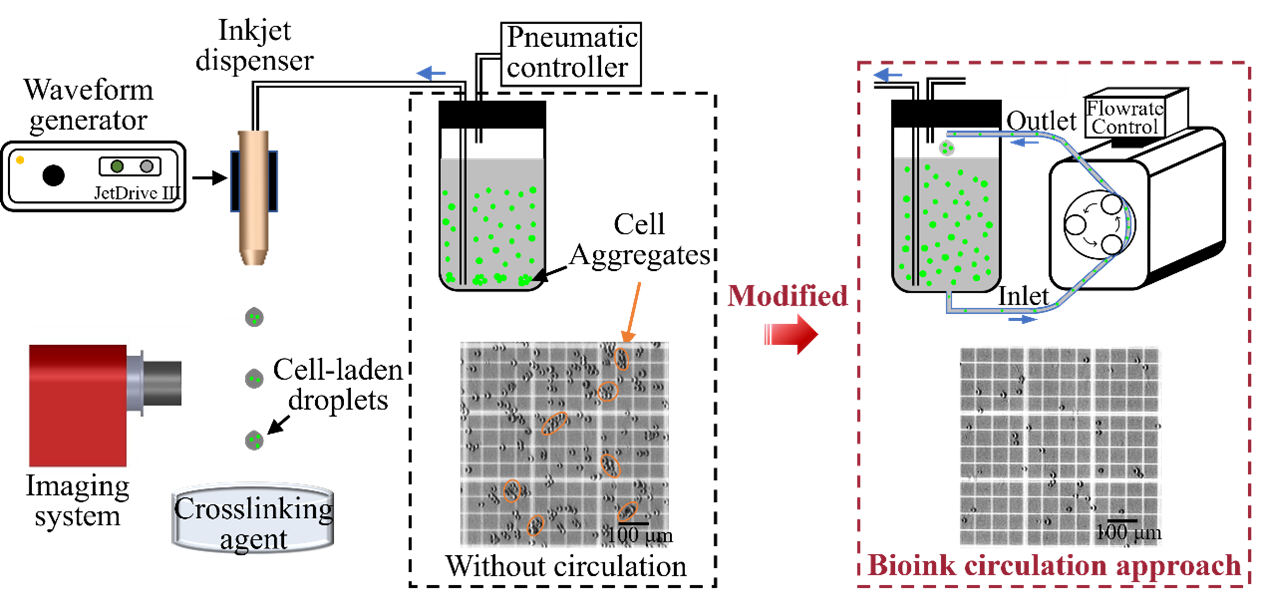

2. Dynamic Circulation in 3D Bioprinting to Mitigate Cell Sedimentation and Aggregation

We have implemented active circulation into the bioink reservoir to mitigate cell sedimentation and aggregation, and demonstrated high effectiveness to mitigate cell sedimentation and aggregation for bioink with both low and high cell concentration. We have constructed a model to predict the dynamic performance of bioink reservoir in cell distribution considering the influence of cell aggregation. The active circulation technology has been filed as a patent PCT/US23/71536. We also received NSF I corps grant to assess the translation potential of the technology in industry.

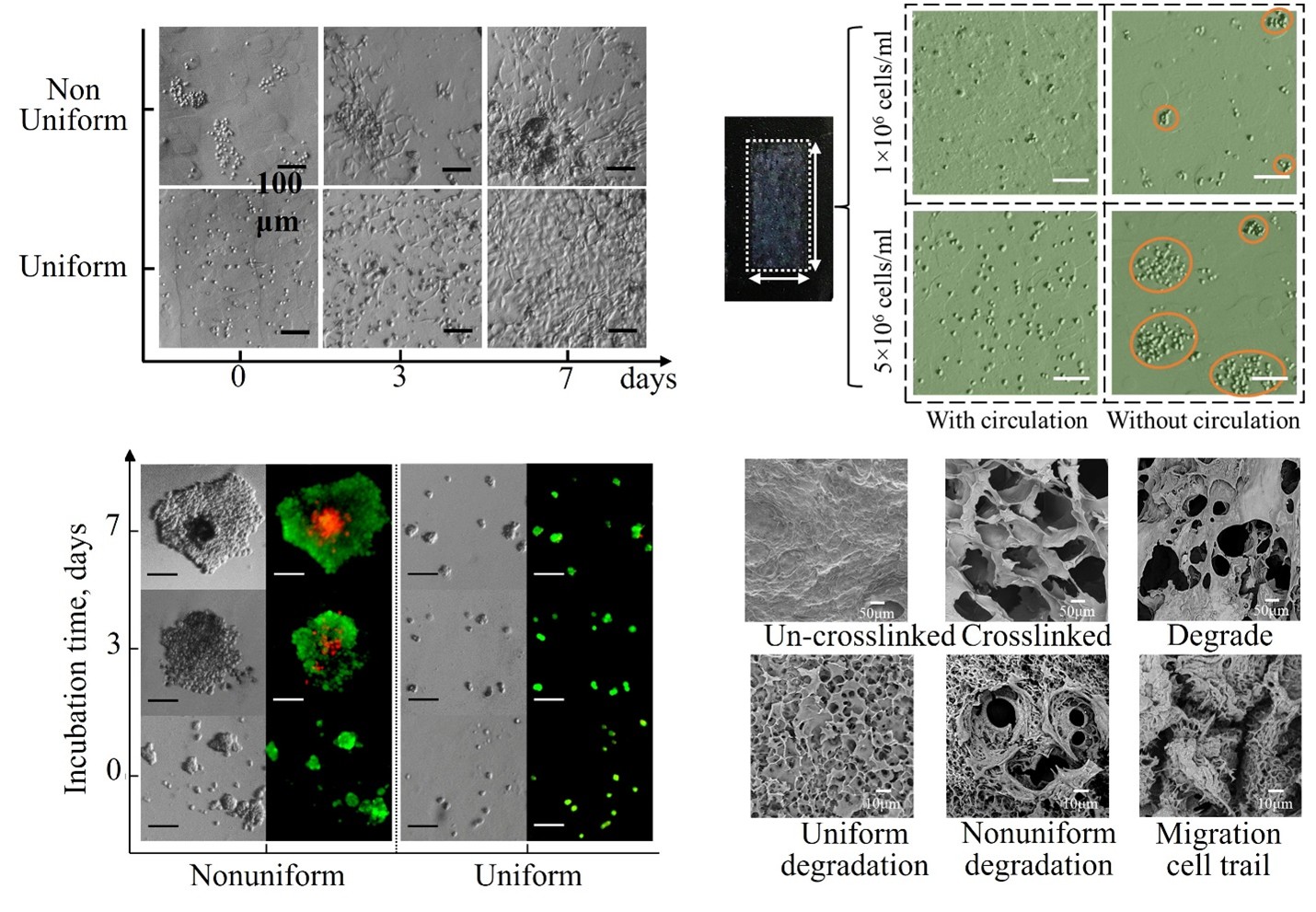

3. Cell-Biomaterial Interaction

In the post-printing incubation, the encapsulated cells interact with the extracellular matrix resulting in eventual functionality of the printed tissues/organs. This is the first paper to elaborate how the spatial distribution of encapsulated cells dramatically alters biomechanical properties and microstructure of 3D printed cellular structures. Specifically, the effects of the cell distribution on post-printing properties and microstructure have been investigated in terms of cell viability, growth & proliferation, mechanical properties, and pore size & microchannels.

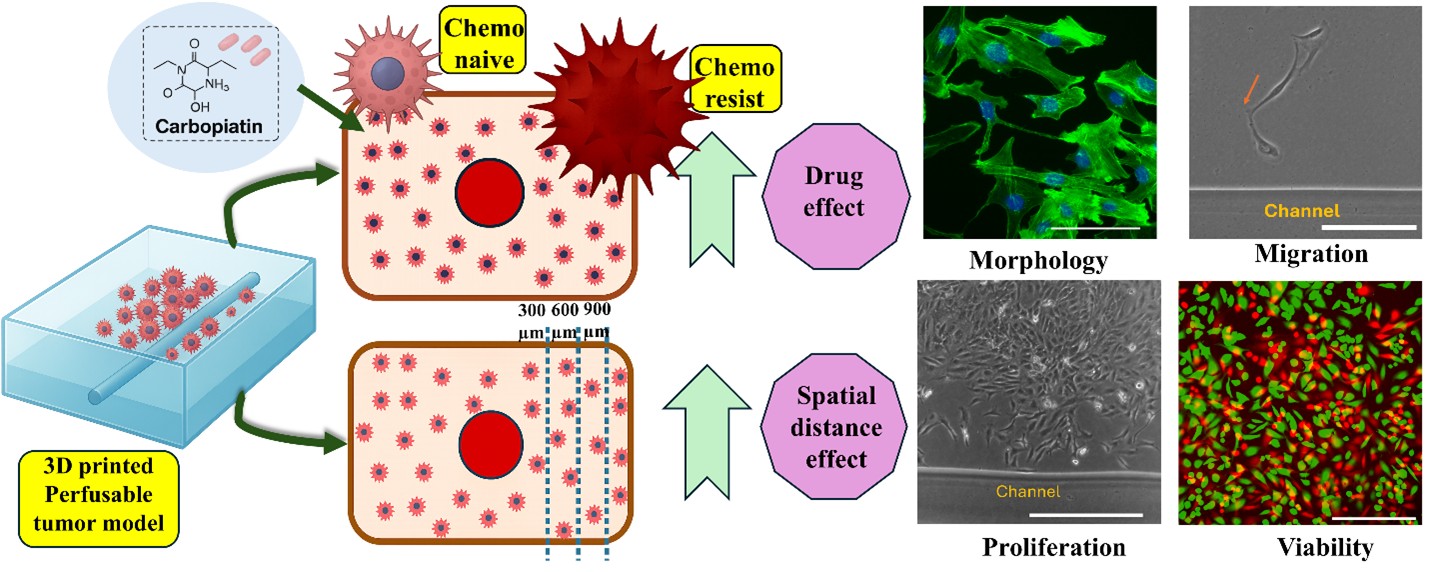

4. Cancer Invasion/Migration using 3D Printed Multicellular Tumor Microenvironment (TME)

We have fabricated a 3D multicellular tumor microenvironment (TME) model to investigate cancer migration behavior. 3D printed TME model with perfusable vascular network is used to mimic the microenvironment of cancer cells within ECM. Ovarian cancer cells and breast cancer cells have been used to investigate migration speed, migration direction, and trajectory with the incubation time. In addition, we also study different behavior and response of chemo-naïve and chemo-resistant cancer cells during chemotherapy in terms of cell viability and proliferation, and migration speed and trajectory.

5. Cell Patterning in 3D Bioprinting

This is truly a technological breakthrough in cell patterning during 3D bioprinting. Our innovative acoustic array-assisted 3D bioprinting technology precisely arranges cells within microscale filaments, closely mimicking the native architecture of tissues and organs to realize physiologically relevant functions of fabricated artificial tissues and organs. This innovative technology is a collaboration with Dr. Jingfei Liu from Mechanical Engineering at Texas Tech University. This research is funded by NSF, entitled “EAGER: Dynamic Cell Patterning in Acoustic Array-Assisted 3D Bioprinting”.

Industrial, Manufacturing, & Systems Engineering

-

Address

Texas Tech University, Box 43061 | Lubbock, TX 79409-3061 -

Phone

806.742.3543 -

Email

imse@ttu.edu