Manufacturing Engineering

Master of Science in Manufacturing Engineering

Master of Science in Manufacturing Engineering

What is Manufacturing Engineering?

Manufacturing Engineering takes ideas from concept generation to working products. It focuses on research, development, and optimization of manufacturing processes, technologies and systems.

What do we do?

- Product design and technology development

- Improvement and optimization of manufacturing processes

- Factory planning and design

- Management of production systems

What will you learn?

- Advanced manufacturing technologies including additive manufacturing, micro-/nano-manufacturing, etc.

- Computer-aided manufacturing including sensors, industrial robots, programmable logic controller, etc.

- Biomedical design and manufacturing including biomedical devices, tissue-engineered scaffolds, etc.

- Manufacturing facilities design: layout planning models, warehouse operations, facilities plan evaluation & selection, etc.

- Sustainable manufacturing: life cycle assessment, sustainable design, sustainability modeling, etc.

Concentration Courses

- IE 5351: Advanced Manufacturing Processes

- IE 5352: Advanced Manufacturing Engineering

- IE 5353: Sustainable Manufacturing

- IE 5355: Computer-Aided Manufacturing

- IE 5356: Biomedical Design and Manufacturing

- IE 5357: Manufacturing Facilities Planning and Design

Who can you work for?

- Equipment and Automation: Boeing, General Motors, Ford, Tesla, Cummins, Caterpillar,

John Deere, 3M, Texas Instruments, Cameron, and more!

- Energy: Exxon, Emerson, GE Energy, Siemens, Chevron, and more!

- Additive manufacturing: 3D systems, HP, Stratasys, FormLabs, and more!

- Semiconductors: Apple, Applied Materials, ASML, Intel, and more!

- Healthcare: GE healthcare, Johnson & Johnson, St. Jude Medical, and more!

Average Salary: $88,222 / yr (Source: Glassdoor)

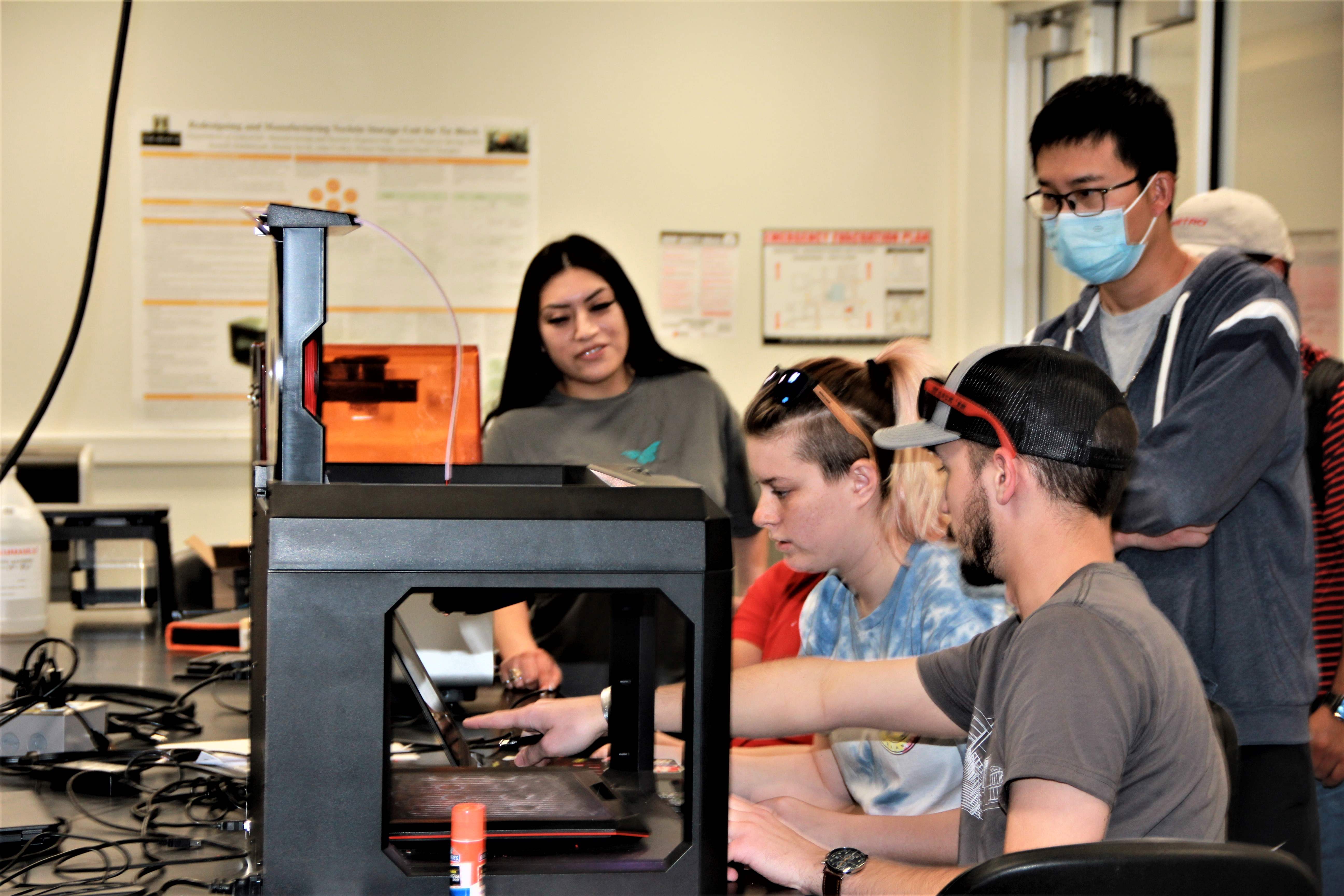

Stinson Family Advanced Manufacturing Technology Laboratory

The Stinson Laboratory is equipped with a series of state-of-the-art advanced manufacturing facility. The equipment include six fused deposition modeling machines, five stereolithography machines, four carbon fiber reinforced composite 3D printer, a coordinate-measuring machine, wire-electrical discharge machining machine, a multijet liquid based 3D printer, a selective laser sintering machine, an optical microscope, a 3D bioprinter, a horizontal tensile tester, a benchtop scanning electron microscope (SEM), a microwriter, a maskless lithography machine, to name a few.

Advanced Manufacturing and Materials Laboratory (AMML)

The Advanced Manufacturing and Materials Laboratory (AMML) holds many state-of-the art facilities including a directed energy deposition additive manufacturing machine, a rotary ultrasonic machine, a nanomechanical testing system, and two universal testers. This laboratory conducts researches on laser additive manufacturing, rotary ultrasonic machining, ultrasonic vibration-assisted manufacturing, nanomechnical and tribological testing, remanufacturing, sustainable manufacturing, and life-cycle assessment processing.

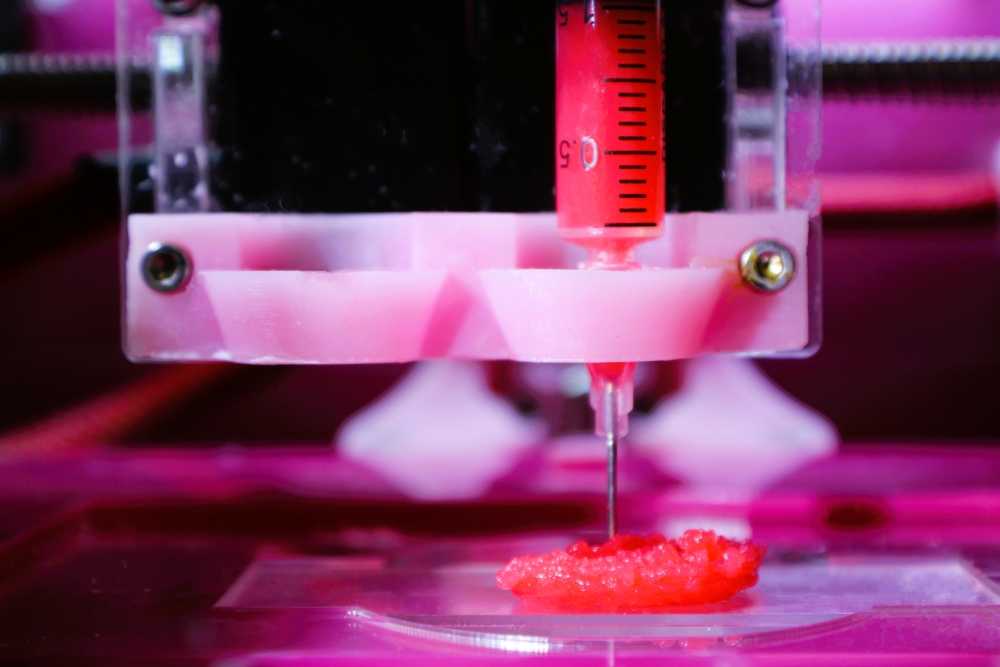

Bioprinting and Biofabrication Laboratory

The Bioprinting and Biofabrication Laboratory focuses on utilizing various 3D printing techniques to fabricate 3D scaffolds for biomedical applications. The lab is equipped with inkjet-based bioprinting system, microextrusion bioprinting system, digital micromirror device (DMD)-based dynamic optical projection stereolithography system. The research interests include 3D bioprinting processes, biofabrication of tissue-engineered blood vessels, organ-on-chips, guided cell migration on microtopographic surfaces, and filament thinning and droplet formation of viscoelastic polymer solutions.

Tissue Assembly and Nanofabrication (Tan) Laboratory

The Tissue Assembly and Nanofabrication (Tan) Laboratory focuses on research and development of novel fabrication technologies for multifunctional materials and biomimetic structures. This lab provides a state-of-the-art environment for exploration and innovation

in micro- and nano-fabrication engineering and aims to incubate solutions for biomedical and environmental challenges. Technologies include 3D bioprinting, electrospinning, direct-write photolithography, and crystal self-assembly.

Contact Us!

Phone: (806) 742-3543

Email:

weilong.cong@ttu.edu

changxue.xu@ttu.edu

Industrial, Manufacturing, & Systems Engineering

-

Address

Texas Tech University, Box 43061 | Lubbock, TX 79409-3061 -

Phone

806.742.3543 -

Email

imse@ttu.edu