The managing director of the Fiber and Biopolymer Research Institute will play a key role in the Zoonotic and Infectious Diseases Research Center.

The use of masks, whether they are cloth, N-95 or some other iteration, is being touted by health care professionals and governmental leaders as the main mitigating act the public can undertake in the battle against the novel coronavirus. Since the COVID-19 pandemic began in the U.S., people in communities across the country have stepped up, making masks for friends and health care workers. Most of those masks have been of the cloth variety. In the future, however, when the worst of this current pandemic is over, future mask production will be influenced by research into what materials and methods offer the best protection against this and future viruses.

That research will almost certainly include results produced from Texas Tech University and its Zoonotic & Infectious Diseases Research Center. A key contributor to that research will be Noureddine Abidi in the College of Agricultural Sciences & Natural Resources.

Abidi, the Leidigh Professor in the Department of Plant and Soil Science and director of the Fiber & Biopolymer Research Institute (FBRI), is a polymer chemist whose research focuses on the physical and chemical characteristics of biopolymers and their functionalization and transformation, which leads to practical, advanced applications. One of those applications is the potential antimicrobial properties of certain natural and manmade fibers.

"I feel that my expertise in biopolymer chemistry and physicochemical characterization could contribute greatly to this new research initiative," Abidi said. "Physical and chemical characterization is important for any field of research. Our instrumental tools and expertise could be used alongside other research to confirm and support the results obtained from various research projects undertaken by members of the newly created center."

Low-grade cotton

One of Abidi's most recent research discoveries could have a huge impact in providing not only protective masks but other personal protective equipment (PPE), while at the same time creating an economic advantage for the cotton industry.

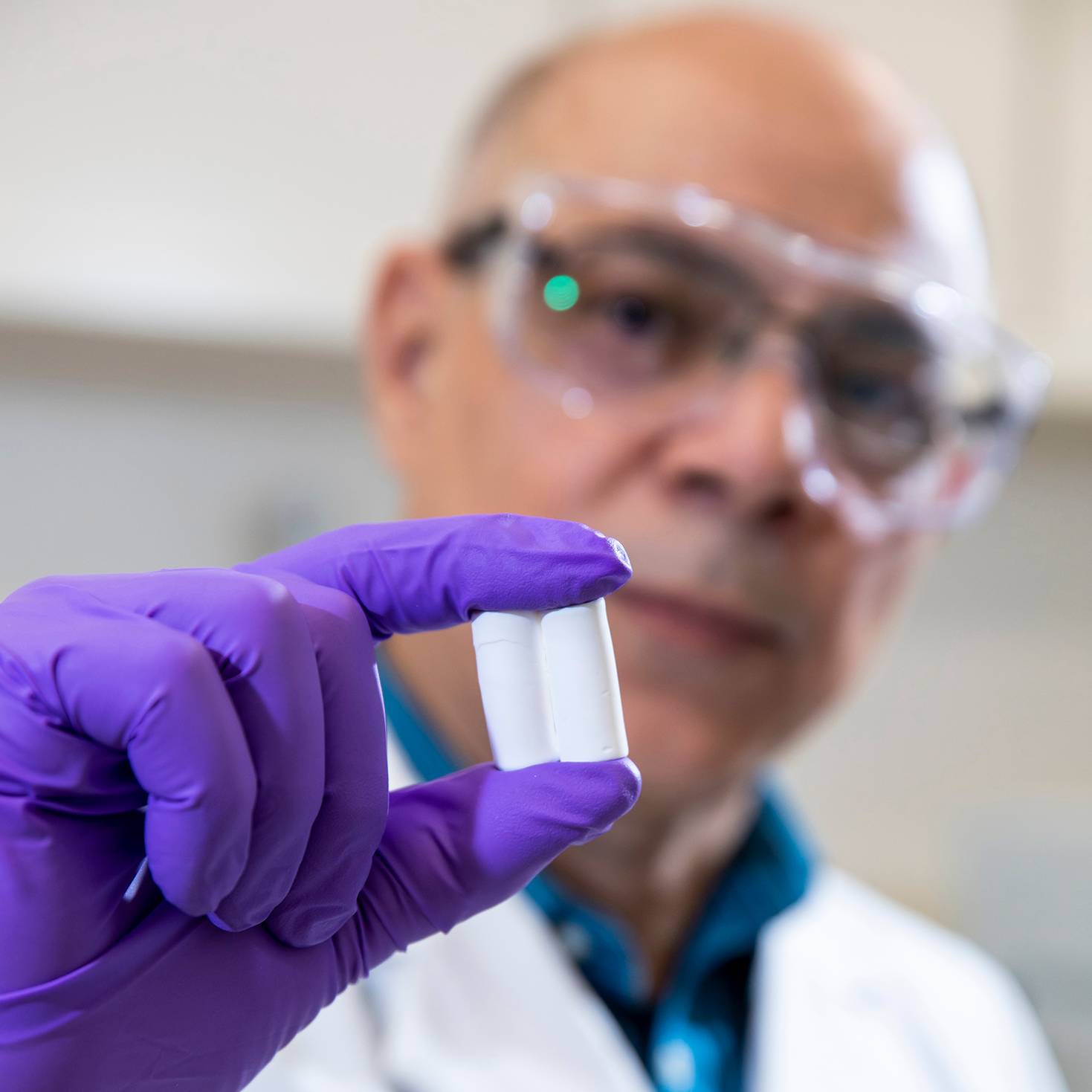

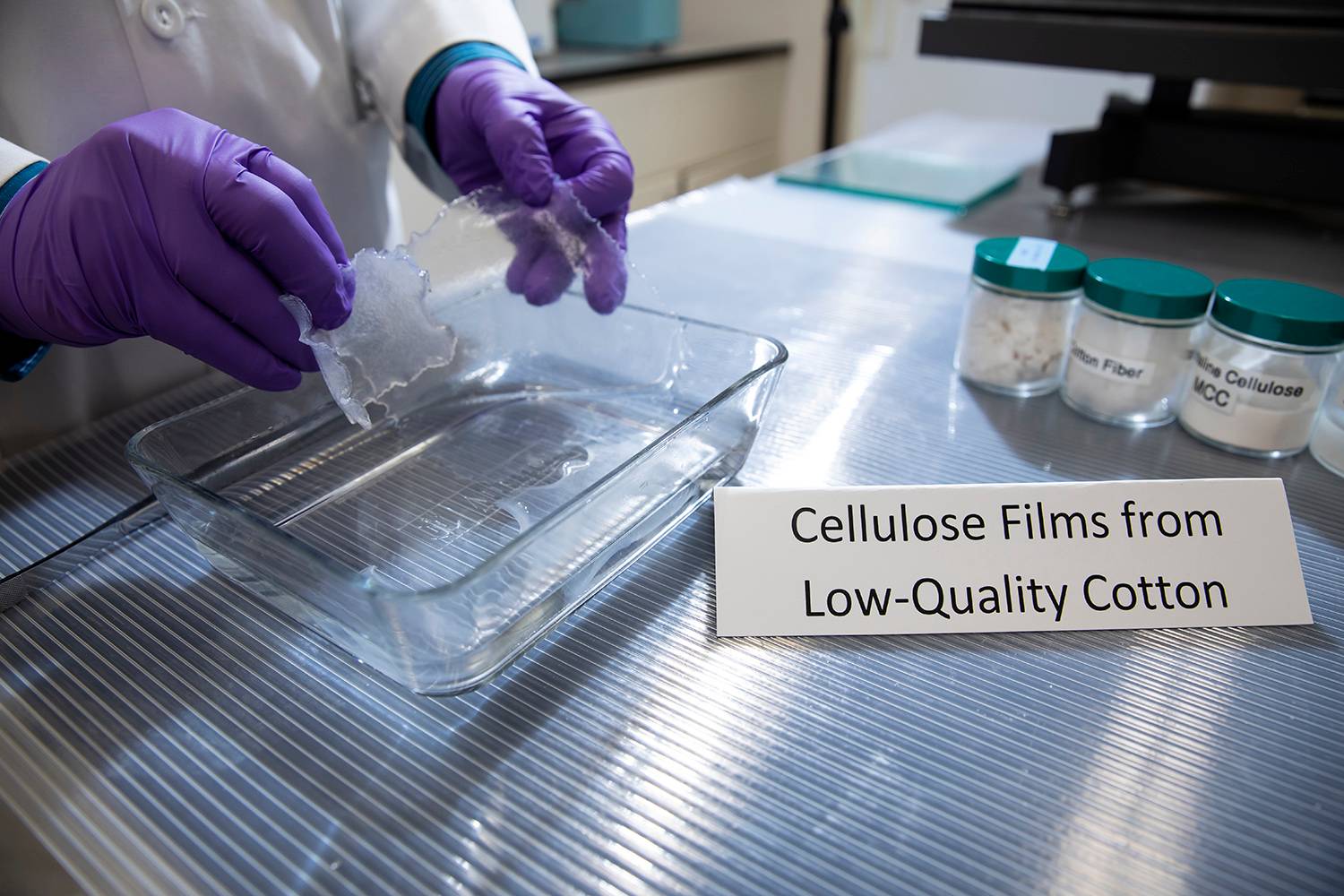

In September, Abidi was awarded a patent for a process he developed that can break down low-grade cotton into pure cellulose, which then can be converted into a gel that can be used in 3D printing, for example, or other processes to create usable, biodegradable products such as bioplastic materials.

"The idea is to find a new use for low-grade cotton or any recyclable that is 100-percent cotton, and trying to replace, to some extent, petroleum-based products," Abidi said when the patent was awarded. "It is still a valuable product that we need to transform into something else."

Abidi's goal with the research is to be able to take the gel from low-grade cotton and use it to replace as many nonbiodegradable products, like plastic trash bags, as possible. Abidi and fellow researchers already have shown in the FBRI laboratory that the process will work, using it to convert low-grade cotton into products such as protective film, which could potentially be used to make face shields for hospital workers caring for coronavirus patients.

The gel also can be used in 3D printers, which can then be used to create myriad products with the potential of helping curb the coronavirus outbreak. During their research, Abidi and his colleagues placed the gel into a 3D printer jet to produce scaffolds or the skeleton of other products, or placed it in a mold to give it a certain shape, such as porous materials. About the only limit to the process is whether there is a need for a product that can withstand specific conditions, such as high humidity, high heat or high strength/elongation.

"The use of a face mask/covering is one approach to effectively prevent airborne infectious diseases," Abidi said. "Although my current research has not been focused on face masks in particular, my expertise in textile and polymer chemistry can be used to develop a new generation of effective face masks that also can incorporate a face shield."

Diverse background

Abidi's previous research has focused on the creation of antimicrobial textiles, self-cleaned textiles and the physicochemical characterization of pollen shells. This is done using Fourier-transform infrared micro-spectroscopy (FTIR), a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas, and thermal gravimetric analysis (TGA), where the mass of a sample is measured over time as the temperature changes.

He also has conducted research using FTIR microspectroscopy imaging characterization of biological tissues such as liver, lung and adipose tissue, serum and plasma, as well as decellularized spinach leaf scaffolds.

Abidi holds a doctorate in theoretical, physical and analytical chemistry from the University of Montpellier II in France. He joined the FBRI in 1999 as a research associate working in chemical finishes and textile chemistry, holding a bachelor's degree in chemistry and a master's degree in polymer chemistry.

He also served postdoctoral stints at the Laboratory of Physical Chemistry of Condensed Matter at Montpelier II and the Material and Membrane Processes Laboratory at the National College of Chemical Engineering of Montpellier, France.

He has served as managing director of the FBRI for the last three years, where he has worked with a diverse staff of researchers, a critical component to working with the Zoonotic & Infectious Diseases Research Center.

"Creating a network of scientists with a multidisciplinary expertise is critical to staying ahead of emerging infectious disease outbreaks," Abidi said. "I hope this new collaboration will lead to building a team with multidisciplinary expertise that can help advance research, share knowledge and access to laboratory equipment and speed up discoveries."

Article by George Watson, Texas Tech Today (July 16, 2020)