VIDEO: 'One of a kind' technology could change the way jeans are made

By: Allison Hirth & Jeff Ramazani

Currently, fabric mills around the world are using millions of gallons of water to dye denim the deep blue color consumers want to wear. That process can now be done more efficiently thanks to research being done at Texas Tech.

VIDEO: The foam-based technology makes denim dyeing more cost-efficient and environmentally

friendly. Click here

VIDEO: The foam-based technology makes denim dyeing more cost-efficient and environmentally

friendly. Click here

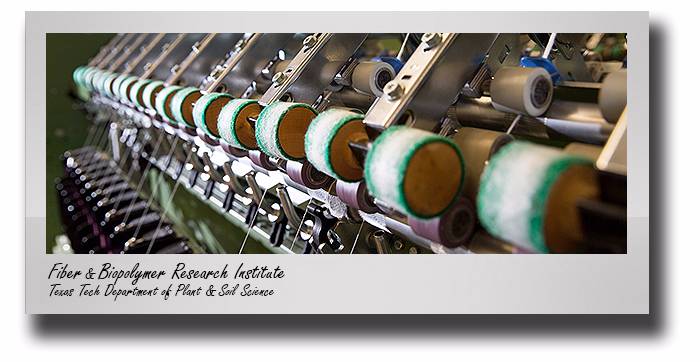

Using foam, a team at the university's Fiber & Biopolymer Research Institute has developed a way to successfully apply indigo dye to cotton yarns. The small-scale, controlled system reduces the amount of water required and lessens the time it takes to complete the process. Dean Ethridge, a research professor with Tech's Department of Plant and Soil Science, is leading the effort.

"This is one of a kind," Ethridge said. "This technology is flexible. It's space efficient and it is amenable to scientific control of the parameters for exact dyeing results."

Located some six miles east of the main campus, FBRI occupies 110,000 square-feet of space allowing Tech researchers to conduct testing and evaluation from the raw fiber stage through the finished textile product. Facilities include a multimedia classroom and conference room, biopolymer research laboratory, cotton phenomics laboratory, cotton ginning laboratory, and cotton processing laboratory (spinning and weaving).

CONTACT: Noureddine Abidi, Managing Director, Fiber and Biopolymer Research Institute, Department of Plant and Soil Science, Texas Tech University at (806) 834-1221 or noureddine.abidi@ttu.edu

1206NM17

Davis College NewsCenter

-

Address

P.O. Box 42123, Lubbock, Texas 79409-2123, Dean's Office Location:Goddard Building, Room 108 -

Phone

(806)742-2808 -

Email

kris.allen@ttu.edu