Dr. Gordon Christopher Awarded $295,000 NSF Grant to Investigate Particle-laden Interfaces with an Interfacial Rheometer

By Amanda Miller

and Dr. Gordon Christopher

We encounter emulsions frequently in everyday life. Emulsions are mixtures of two or more liquids that are normally immiscible (not uniformly mixed), and can be found in many different consumer products, from salad dressing to shampoo. These mixtures, however, have the inherent tendency to separate over time — the way water and oil does when combined — presenting some difficulty due to the fact that they do not naturally remain dissolved or properly mixed.

Industry has invented ways of combating this difficulty by attempting to change the rheology, or flow properties, of the materials in emulsions. This is often accomplished through the use of particle-laden interfaces, an innovative technique to change the way the individual liquids react to one another. Utilizing small particles adsorbed to (or adhering as a thin film around) the surface of emulsions and foams, these interfaces can often prevent or reduce the separations. These advancements have helped scientists to create more viscoelastic products.

Purely viscous materials, such as honey, for example, are considered "thick" liquids because they exhibit resistance to deformation over time. When honey is poured, it resists changing shape but will eventually — even if slowly — flow. Purely elastic materials, like a rubber band, can bend and stretch when deformation forces are applied, but then "snap" back to their original shape once the stress is removed. Viscoelastic materials have characteristics of both, and are therefore beneficial to commercial manufacturing of common products because they are easier to control during manufacturing processes and make the creation of stronger, more durable products possible. For example, a more viscoelastic material could be used to create a cheaper and easier-to-make phone case, taking advantage of viscous properties during manufacturing to save time and energy while creating a final product that has superior durability due to its elasticity. However, there has yet to be a set of rules discovered to explain the precise ways in which adsorbed particles and their properties affect the interfaces and the material's end viscoelasticity.

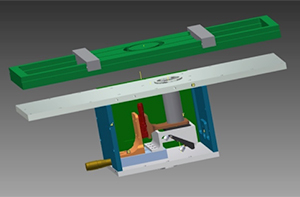

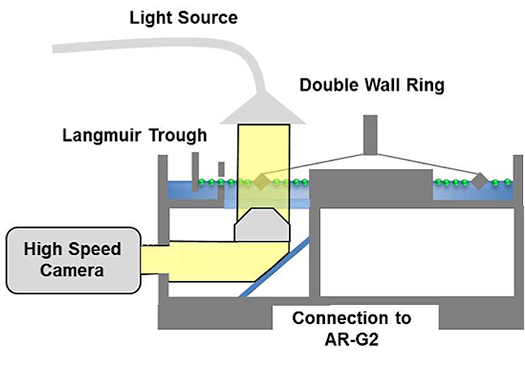

In response to this demand in industry, Dr. Gordon Christopher, assistant professor of mechanical engineering at Texas Tech, is conducting research with particle-laden interfaces using a highly specialized interfacial rheometer developed and modified at Texas Tech. The rheometer will allow Christopher and his team to simultaneously take measurements of an interface, and actually view the adhered particles and their specific arrangement. This research will include exploring the way that certain particle properties, composition, and the arrangements they take on the interface — also called mesostructure — can impact the rheology of the interface.

Backed by a $295,000 grant from the National Science Foundation, Christopher plans to work with graduate students, as well as a few highly qualified undergraduate students, on this project. There is also great potential to collaborate with other departments at the university in utilizing the interfacial rheometer to yield discovery. Different applications of the rheometer include investigating biofilms and liquid marbles with greater accuracy than would have been possible before.

Starting at the microscale, Christopher will study interfaces less than 10 microns in size to find the direct connection between physical structure and rheology by viewing changes that occur on the interface. These findings can then lead the way to research regarding particles adhered to droplets closer to a milliliter in size, and eventually applications of these discoveries to large scale suspensions, including emulsions and foams.

With this information, industry would be able to design interfaces to respond directly to characteristics needed in suspension materials. It would become possible to know exactly what particles with which characteristics, composition, and mesostructure are necessary to achieve a specific rheology. This rational design of materials and knowledge of emulsions that have particle-laden interfaces could be applied to many different fields including manufacturing of food and cosmetic products, pharmaceutical production and delivery, and even enhanced oil recovery.

Grant Title:

Role of Composition on Mesostructure-Flow Interaction and Rheology of Particle Laden Interfaces

Edward E. Whitacre Jr. College of Engineering

-

Address

100 Engineering Center Box 43103 Lubbock, Texas 79409-3103 -

Phone

806.742.3451 -

Email

webmaster.coe@ttu.edu