Researchers at Texas Tech and Yale Explain How to Make the Hardest Metal Pliable

Researchers at Texas Tech University and Yale University have discovered a way to predict and control the properties of metallic glasses, yielding a highly versatile material that looks like metal, is moldable like plastic, but stronger than steel.

Metallic glasses are unique because they combine traits of metals, plastics, and glasses in one material. These materials conduct heat and electricity like metals, but their glassy structure makes them moldable like plastics, and hard like glasses. In the process of creating these metallic glasses, it has been difficult to predict the exact properties of the end product, as the materials can be ductile or brittle depending on their composition, sample size, and preparation conditions. Despite numerous efforts in the past, no single theory could explain the effect of all of these factors on the properties of metallic glasses.

Dr. Golden Kumar, assistant professor of mechanical engineering at Texas Tech, and Dr. Jan Schroers, professor of mechanical engineering and materials science at Yale University, have developed a model that can explain why some metallic glasses are always ductile or brittle, whereas others are sensitive to processing and aging. The model is based on the metallic glass' fictive temperature.

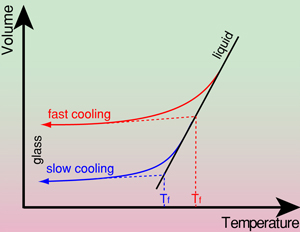

The study, “Critical fictive temperature for plasticity in metallic glasses,” is published in the journal Nature Communications and reveals that there is a critical fictive temperature to obtain a glassy state capable of plastic deformation. The study shows there is a critical cooling rate, based on the critical fictive temperature, for pliability in metallic glasses. If the glass is cooled more slowly than the critical cooling rate, it will be brittle.

“By comparing the critical fictive temperature values for different metallic glasses, we can now tell which one will be ductile or brittle under typical conditions,” Kumar said. “This can explain why some metallic glasses were always brittle; their critical fictive temperature is beyond experimentally accessible fictive temperature.”

“The model will help to develop an alloy-specific preparation recipe for obtaining plasticity in metallic glasses," Schroers explained. “This is a crucial step toward predictive models for plastic deformation of metallic glasses.”

Other co-authors who contributed to the study are Pascal Neibecker and Dr. Yanhui Liu at Yale.

Kumar joined the Department of Mechanical Engineering at Texas Tech in 2012. He received a Ph.D. from the Technical University in Dresden, Germany in 2005, a Master of Technology in Materials Science and Engineering from the Indian Institute of Technology in Kharagpur, India in 2000, and a Bachelor of Science from Panjab University in Chandigarh, India in 1996.

Edward E. Whitacre Jr. College of Engineering

-

Address

100 Engineering Center Box 43103 Lubbock, Texas 79409-3103 -

Phone

806.742.3451 -

Email

webmaster.coe@ttu.edu