FBRI is now full circle: from gin to jeans

Out on the Texas High Plains a one-of-a-kind, cotton micro-gin has officially gone on-line just in time for harvesting season. The custom-built ginning laboratory is located at Texas Tech University's Fiber and Biopolymer Research Institute and is expected to help put the sprawling agricultural research center near the top of the nation's most sophisticated research gin facilities.

“This equipment gives us the ability to closely match ginning conditions that cotton fibers will experience in the real-world, commercial ginning conditions,” said FBRI Managing Director Noureddine Abidi. “It gives us the ability to observe the actual performance that can be expected from a particular cotton when processed commercially.”

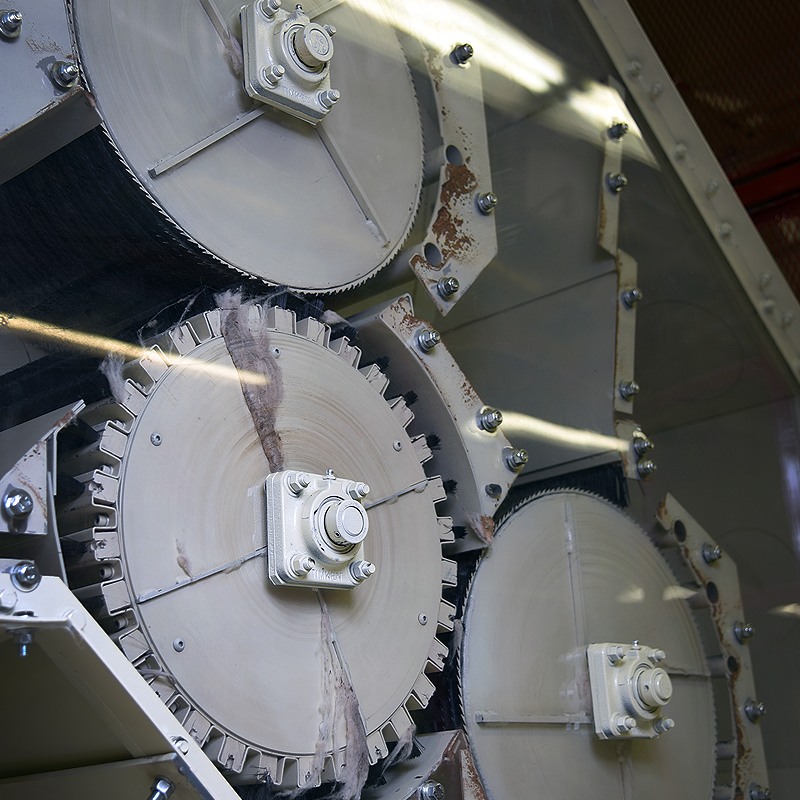

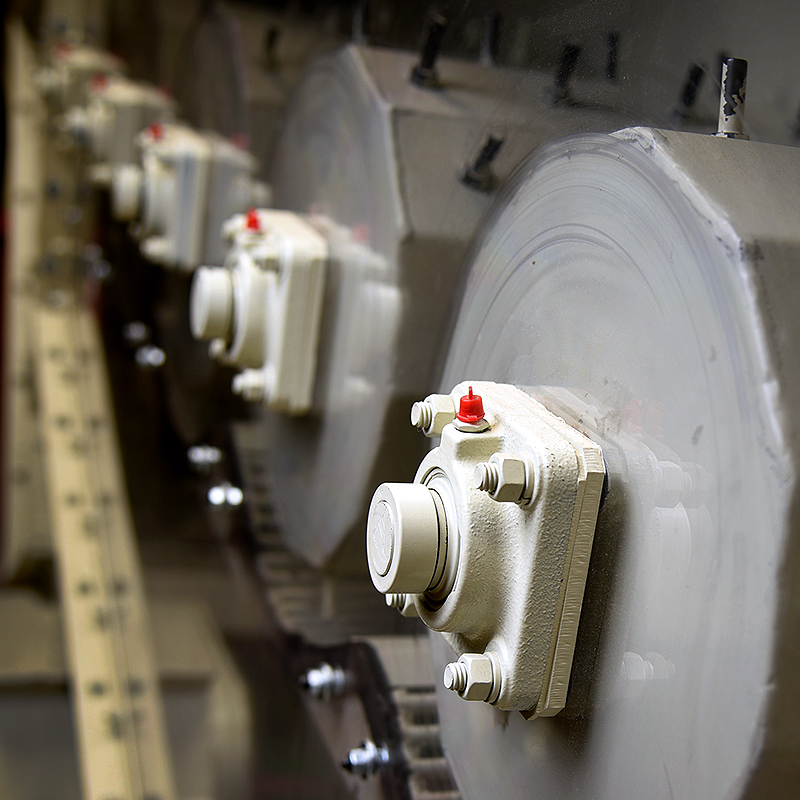

Tech's FBRI micro-gin uses transparently-sided, scaled-down versions of commercial Lummus cotton ginning equipment, which can be found in many gins across the South Plains and the state in general. Georgia-based Lummus Corp. is a leading supplier of machinery and replacement parts for the cotton ginning industry.

In terms of specific features, Abidi said their micro-gin consists of cotton pre-cleaning equipment (hot air cleaner, stick machine, and feeder), one 24-saw gin stand (to separate the lint from the seeds), and an air-jet lint cleaner followed a single-stage lint cleaner (to remove trash particles and contaminants from the lint). The equipment is fully automated and controlled by the same software program that Lummus uses to control modern, full-size cotton gins.

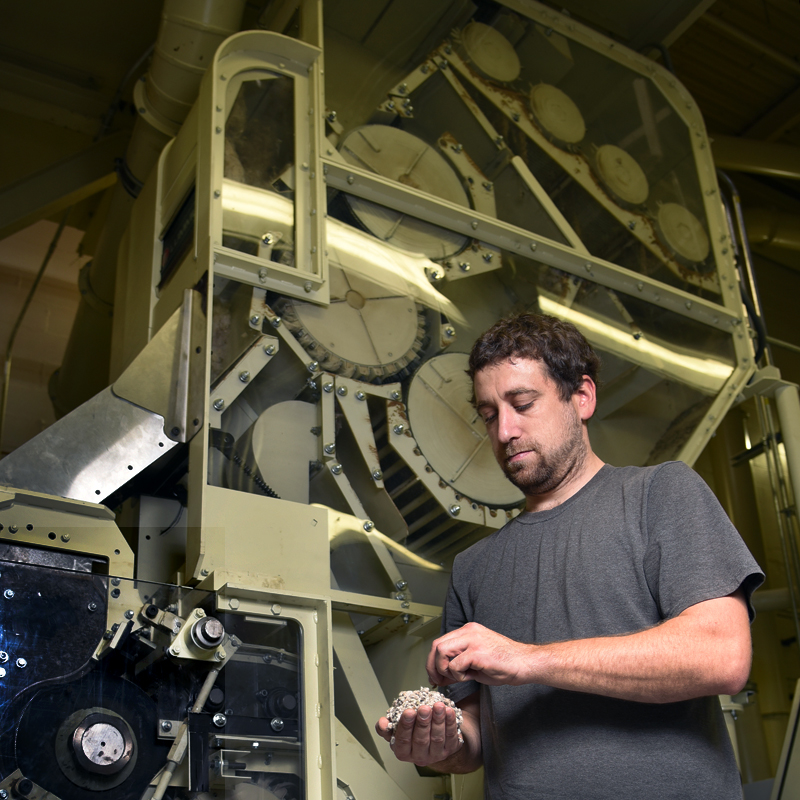

In its current configuration, Abidi said the micro-gin is capable of processing more than 2,500 pounds of raw cotton per hour (constant throughput). “We hope to be able to process between 75 to 100 [cotton] breeder's samples per day once the harvest season begins,” he said.

Asked why go small, Abidi explained that the micro-gin serves two critical purposes:

- Processing and ginning of cotton breeder/research samples for turnout and fiber quality testing

- Educate undergraduate and graduate students on the inner-workings of the various machines via the equipment's clear siding.

“Both are a valuable additions,” Abidi said. “We now have the ability to process cotton from a module in the field all the way to a piece of textile fabric, and give detailed educational tours of all of the equipment in operation throughout the process.”

Looking ahead, FBRI leaders hope that the micro-gin will be an asset to cotton breeders by helping them produce cottons that perform better than current varieties when processed through a commercial cotton gin. “As the industry is moving in more quality-oriented directions, we must keep producing higher-quality fibers to keep up with the demand,” Abidi said.

In addition to FBRI's new micro-gin, the facility has a smaller, 11 saw stand-alone cotton gin, i.e. with no lint cleaning, and a small roller gin for additional research and ginning capacity if needed. The ginning equipment gives Texas Tech agricultural researchers the capacity to process cotton samples from a single boll to a full size module if required.

Located some six miles east of the main campus, FBRI occupies 110,000 square-feet of space allowing Tech researchers to conduct testing and evaluation from the raw fiber stage through the finished textile product. Facilities include a multimedia classroom and conference room, biopolymer research laboratory, cotton phenomics laboratory, and cotton processing laboratory (spinning and weaving).

Written by Norman Martin

CONTACT: Noureddine Abidi, Managing Director, Fiber and Biopolymer Research Institute, Department of Plant and Soil Science, Texas Tech University at (806) 834- 1221 or noureddine.abidi@ttu.edu

Davis College of Agricultural Sciences & Natural Resources

-

Address

P.O. Box 42123, Lubbock, Texas 79409-2123, Dean’s Office Location: Goddard Building, Room 108 -

Phone

(806)742-2808