Advanced modeling, control, and monitoring for energy, healthcare, and engineering systems

The ever-increasing complexity, dynamics, and high dimensionality of modern systems have become significantly relied on real-time decision-making, high reliability, and efficient operation. Yet, they face challenges such as unpredictable environments, resource limitations, and safety requirements. Dr. Qiugang “Jay” Lu, an assistant professor from the Department of Chemical Engineering at Texas Tech University, leads an interdisciplinary research program, to integrate advanced automatic control, artificial intelligence, and optimization, to address these challenges. The research scope of his group expands across various applications including Lithium-ion batteries, industrial manufacturing, and biomedical applications, towards sustainable energy solutions, effective healthcare delivery, and innovative engineering.

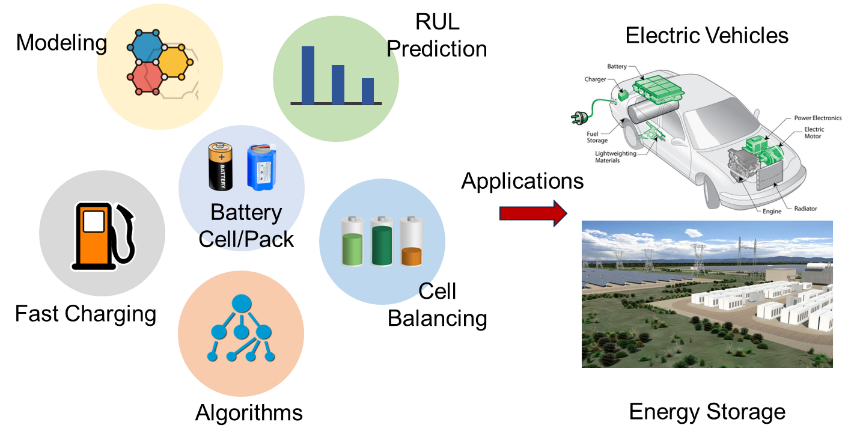

Fig. 1: Main components in intelligent battery management systems developed by Dr. Lu group and the potential applications.

One research theme in Dr. Lu’s group aims to improve the management of complex energy storage systems, by enabling efficient, safe operation, and reliable prediction of the health and lifetime of energy systems. For example, Dr. Lu’s NSF CAREER project focuses on developing innovative management frameworks for battery cells and packs. These frameworks integrate deep learning, reinforcement learning, operating data, and battery physics models to create smarter and safer fast-charging protocols, more accurate prediction of battery remaining useful lifetime, and effective control algorithms to balance different cells in the pack (Fig. 1). In addition, his lab also studies the optimization of other energy systems such as HVAC systems, and the coordination of energy storage with power grids for reducing energy cost and improving economic savings.

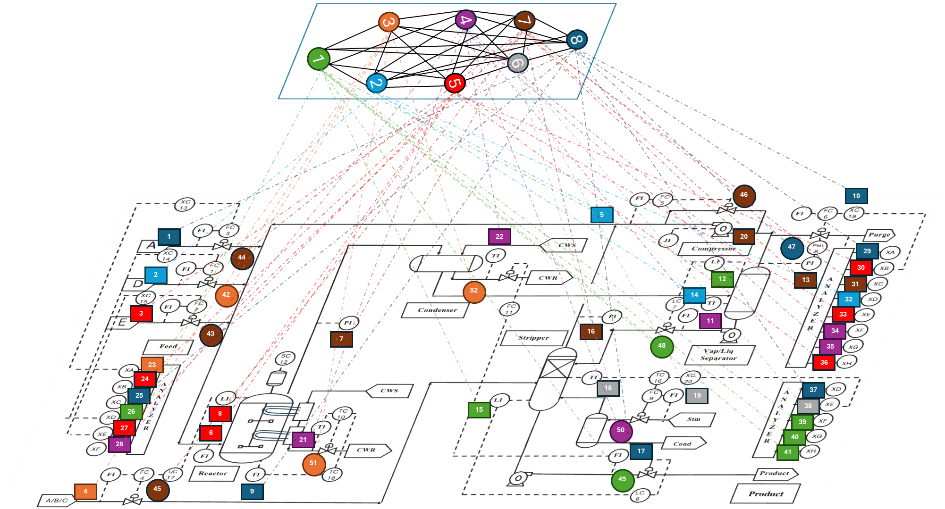

Dr. Lu’s group also studies the development of innovative control algorithms and process monitoring methods for dynamical systems such as chemical plants, buildings, and vehicles. The research in this direction aims at developing first-principle or data-driven models, upon which advanced controllers, such as model-predictive control and reinforcement learning-based control, are enabled for enhanced product quality and reduced operation costs with constraint satisfaction. In addition, the group combines statistical process control with deep learning to establish sensitive and reliable algorithms for the detection and diagnosis of system faults

(Fig. 2). This is critical for ensuring personnel and equipment safety and reducing economic loss.

Fig. 2: Hierarchical graph neural networks proposed by D. Lu group for improved fault diagnosis of chemical processes.

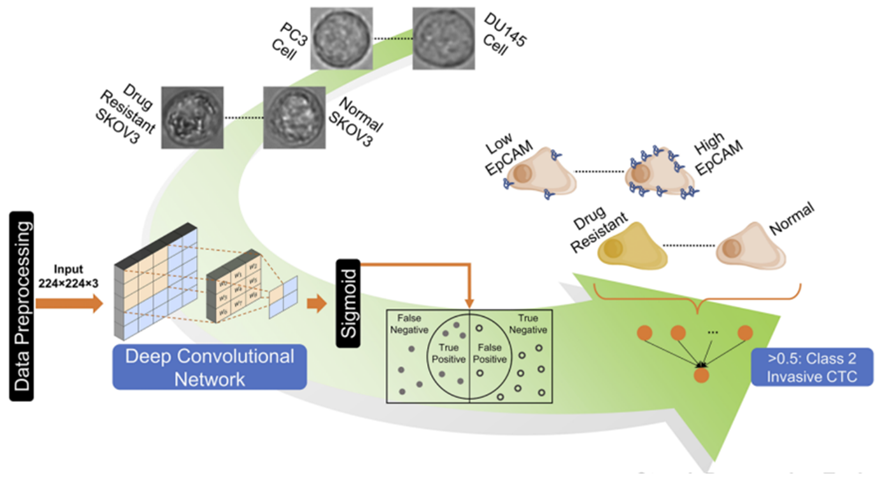

In collaboration with Dr. Li and Dr. Gomez in the Chemical Engineering Department, the research of Dr. Lu’s group has also extended to the disease diagnosis across various biomedical applications. These joint efforts aim to tackle the emerging challenges in this area by integrating advanced artificial intelligence with innovative microfluidic devices and magnetophoresis (Fig. 3).

Fig. 3: Circulating tumor cell subtype classification with artificial intelligence based on cell images captured by microfluidic devices (collaborated with Dr. Wei Li).

Chemical Engineering

-

Address

P.O. Box 43121, Lubbock, TX 79409−3121 -

Phone

806.742.3553 -

Email

che@ttu.edu