Dr. Siva Vanapalli Receives Prestigious NSF CAREER Award for Microfluidic Parking Networks

By Jeff Sammons

Dr. Siva Vanapalli, an assistant professor of chemical engineering at Texas Tech, has been selected to receive a $400,000 2012 NSF CAREER Award from the National Science Foundation. The five-year award recognizes his career development plan entitled, "Collective hydrodynamics of confined drops in microfluidic parking networks". His proposed research focuses on the fundamental understanding of the traffic and parking of tiny water drops in networks of microchannels that will ultimately yield inexpensive miniaturized devices for rapid screening applications in medicine, biology, and materials science.

In the pharmaceutical industry, scientists conduct chemical and pharmacological tests to discover and produce new drugs for treating diseases affecting human health. The initial discovery process consists of screening hundreds of thousands of molecules to identify potential drug compounds. The process continues by varying the dosage of these candidate drugs to figure out the optimal concentration required for effective treatment.

To conduct this screening, drug companies employ hundreds of robots that carry out millions of pipetting, dispensing, and mixing steps to identify the candidate drug. The costs for this high throughput screening operation run into tens of millions of dollars because of the need for extensive infrastructure and large quantities of reagents. Because of the large library of molecules, this first step in making the drug can take many months to accomplish.

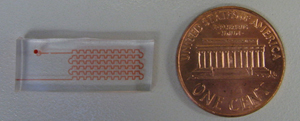

New potential exists in this industry for the use of tiny microfluidic devices. These microfluidic devices are like tiny plumbing systems with "pipes" that are the size of human hairs. They are fabricated using methods similar to those employed in the semiconductor industry to manufacture computer chips. Scientific research has shown that these microfluidic devices can be used to produce extremely tiny water drops, whose volumes are about a thousand times less than the pipetting volumes used by robots in the drug industry.

Although drops can be reliably produced using these miniaturized devices, it has been difficult for scientists to immobilize drops of controlled volume and add or remove reagents from these drops — key steps that mimic conventional pipette-assisted dispensing and dilution of fluids.

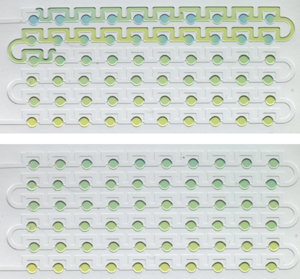

Vanapalli has developed new strategies that allow arrays of nanoliter-scale water drops of controlled volumes to be immobilized in microfluidic devices and also provide the ability to vary concentrations of reagents or other materials from drop to drop in the arrays.

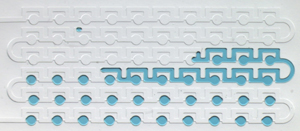

His design involves the creation of microfluidic parking networks (MPNs) within the miniaturized device. Like spaces in an automobile parking lot, trains of water drops and/or long plugs travel down the microfluidic tubes and by effective control of their traffic using fundamental principles of fluid flow, the drops are routed into droplet "parking spaces." The ability to create the "parked" drops is similar to spotting of fluids by robot-aided pipetting systems. Hundreds of nanoliter-scale drops can be parked within few seconds and drug reactions can be monitored in many individual drops simultaneously, enabling rapid quantitative information on drug effectiveness.

Another important breakthrough from his design of parking networks was the ability to purposefully introduce collision of parked drops and moving water plugs to control reagent concentration from drop to drop in the array. This process allows a simple means to dilute reagent concentration in parked drops, enabling rapid identification of optimal dosage of drug concentration.

As part of the CAREER award, Vanapalli will focus on experimental and modeling efforts to predict how water drops move in these parking networks. The scientific results of this work could lead to significant cost and time savings for the drug industry. By carrying out screening experiments at a fraction of the time and cost, his technology has the potential to accelerate drug discovery, making the cost of drugs affordable to consumers.

Vanapalli further plans to explore new opportunities for these devices. For example, conventional methods are not able to quantify the response of individual bacteria to antibiotics. Because the nanoliter-scale parked water drops can capture one or more bacteria, his approaches could be used to study the interactions of single bacteria with antibiotics, helping scientists to understand how bacteria react or mutate when exposed to various concentrations of the antibiotic. Similar approaches could be used to identify chemotherapy-resistant cancer cells. These new opportunities will be pursued in collaboration with Dr. Kendra Rumbaugh, an assistant professor of surgery at the Texas Tech University Health Sciences Center, and Dr. Jerzy Blawzdziewicz, a professor of mechanical engineering at Texas Tech, as part of the Texas Tech Transdisciplinary Research Academy.

Vanapalli joined the Department of Chemical Engineering in the Whitacre College of Engineering as an assistant professor in 2008. He received a Ph.D. in Chemical Engineering from the University of Michigan in 2006, a Master of Science in Food Science in 2001 from The Pennsylvania State University, and a Bachelor of Technology in Agricultural and Food Engineering in 1998 from the Indian Institute of Technology.

Edward E. Whitacre Jr. College of Engineering

-

Address

100 Engineering Center Box 43103 Lubbock, Texas 79409-3103 -

Phone

806.742.3451 -

Email

webmaster.coe@ttu.edu