Center for Emerging Energy Sciences

Precision Metrology & Precision Measurement Science:

Vacuum Calorimeter

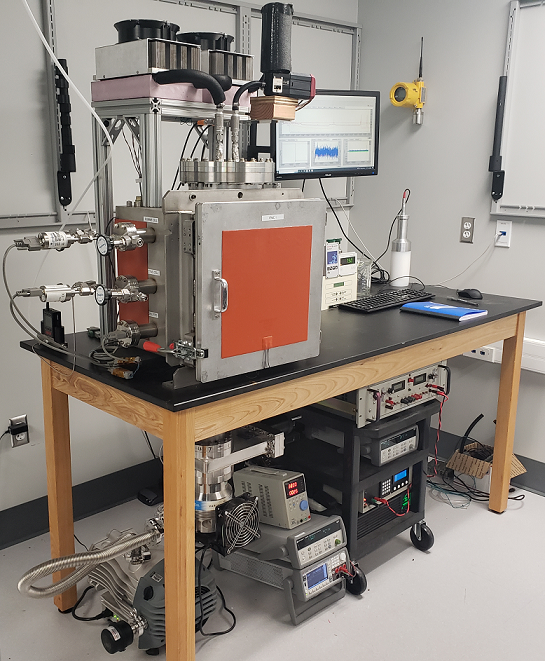

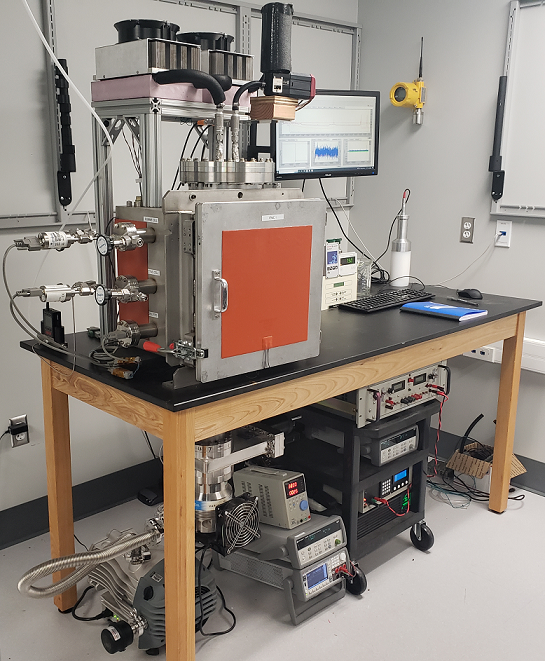

An open-system differential vacuum calorimeter was design and developed at our laboratory.

A calorimeter is used to measure the heat output of a system contained within the

calorimetric boundary. The calorimeter is contained within the vacuum vessel, and

operated in the Knudsen regime, to eliminate nonlinear convective losses. Superinsulation

has been used to reduce radiative transfer with-in the vacuum vessel. A differential

calorimeter approach was used to improve the calorimetric response via common-mode

rejection.

A scroll pump (Edwards nXDS15i) and 6-inch turbomolecular pump (Varian Turbo-V 300HT)

are used to achieve high vacuum (1E-7 torr). Commercially available thermoelectric

modules (TEM) are used both as passive heat-flux sensors as well as active heat pumps.

The heat pumps are utilized to control an isothermal reservoir to provide a reference

temperature for the passive TEMs. A custom fabricated liquid cooled heat-sink has

been utilized to remove waste heat generated by the heat pumps. The active TEMs are

controlled via a bipolar proportional-integral-derivative (PID) controller (TE Technology

TC-720); the control reference is a 15 kΩ thermistor embedded into isothermal reservoir.

The calorimeter was designed to house two containers, an active container, and a control

container. Two different container styles were also evaluated: a wet container used

for electrochemical cells, and a dry container used for gaseous environments. Operating

temperature is limited to 250 °C because of the heat pumping capability of the TEMs

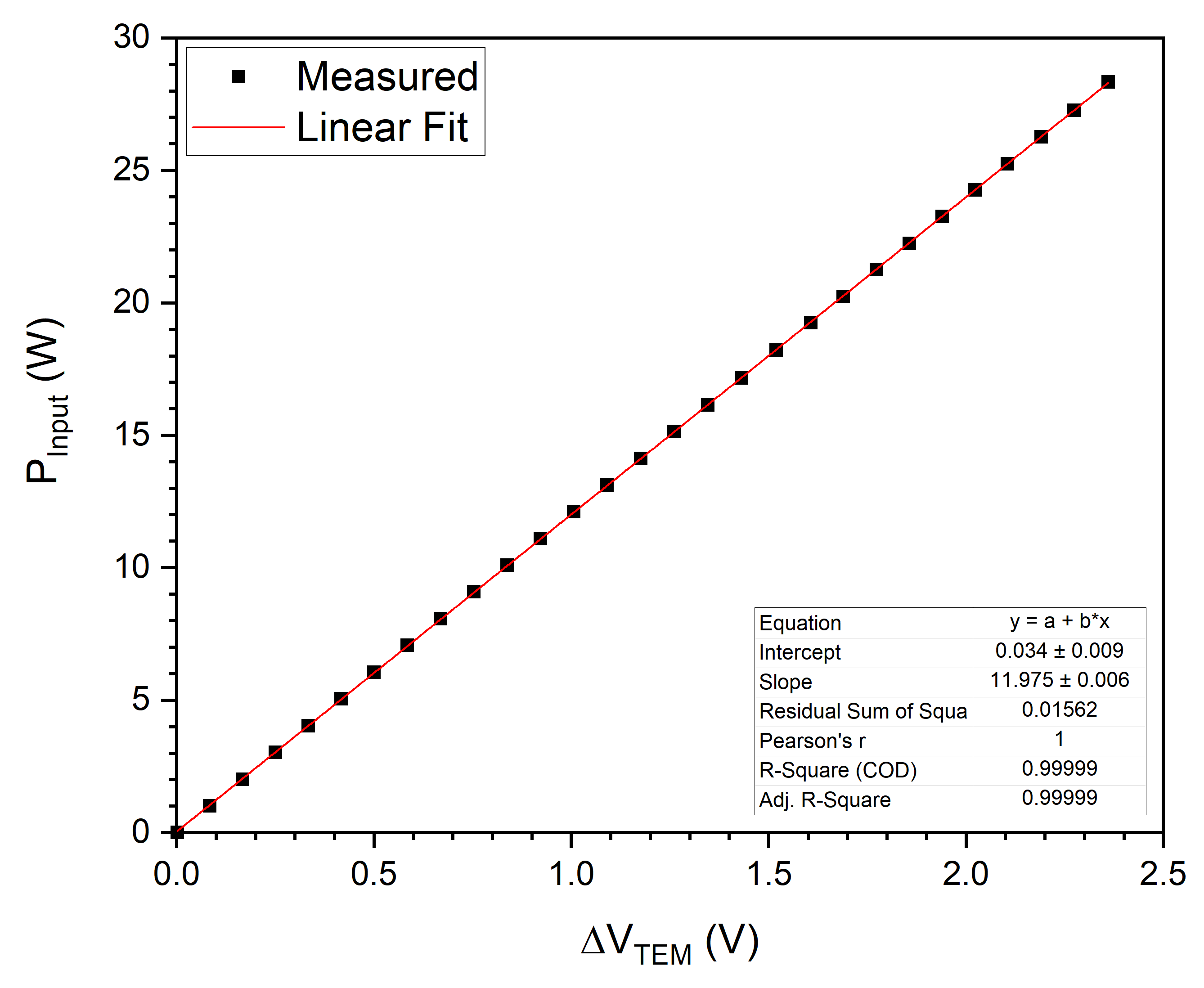

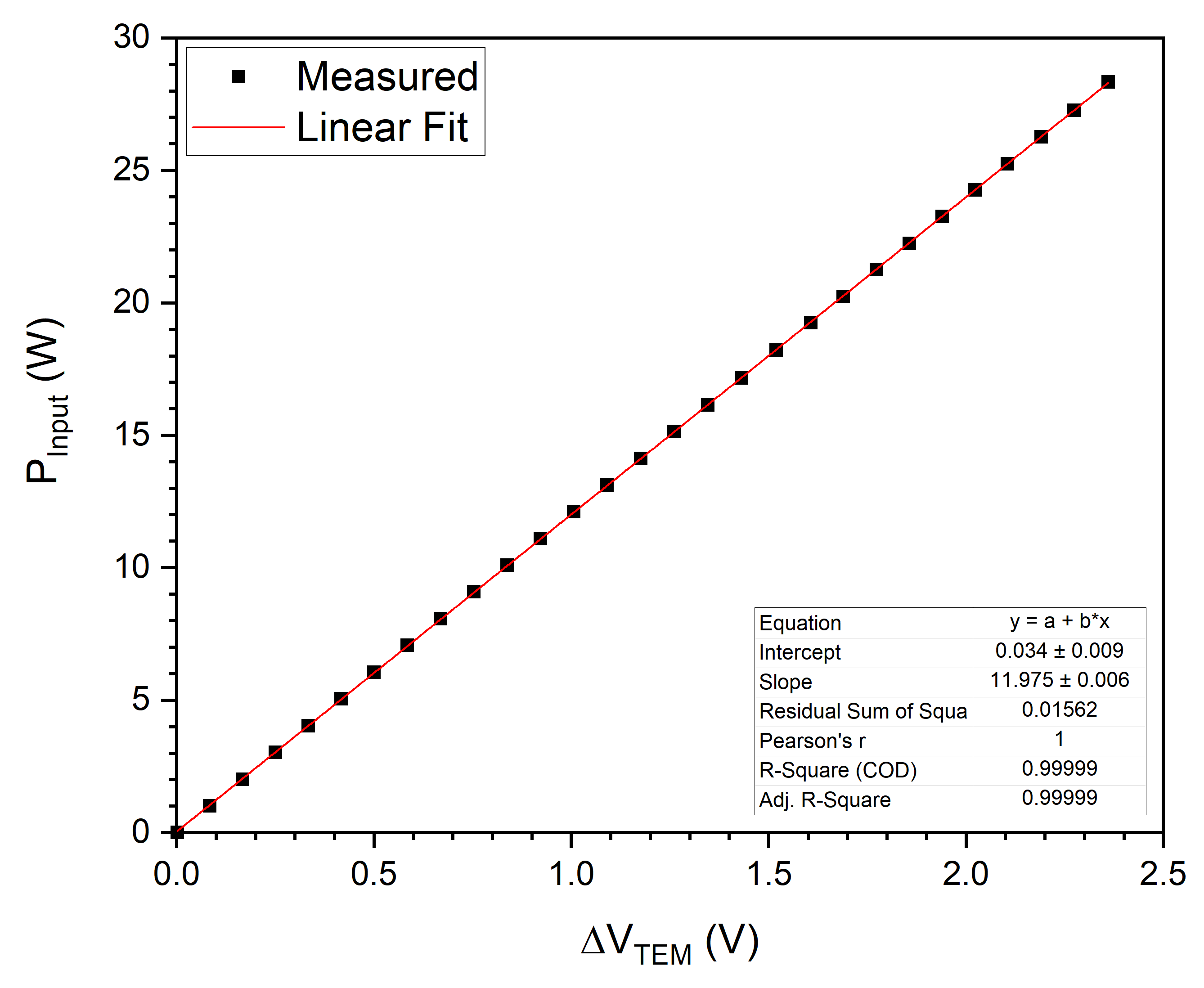

used to control the isothermal reservoir temperature. The calorimeter was designed

for input powers ranging from 1 mW to 28 W; linear calibration up to 28 W yielded

a Pearson's r exceeding 0.999.