Center for Emerging Energy Sciences

Lab Capabilities

The following is a condensed list of specific items referenced in the ARPA-E proposal:

AI feature identification: depts.ttu.edu/phas/cees/Ref/2a.php

Helium outgassing table: depts.ttu.edu/phas/cees/Ref/2c.php

Tritium Extraction PPT: depts.ttu.edu/phas/cees/Ref/Q_Tritium.pdf

Deuterium and protium purification: depts.ttu.edu/phas/cees/Ref/2d.php

FT-ICR Mass Spectrometer: depts.ttu.edu/phas/cees/Ref/2e.php

Vacuum Calorimeter: depts.ttu.edu/phas/cees/Ref/2f.php

The CEES lab has the following capabilities, measurement devices, and equipment available for use. Click each image for additional details and specifications:

Texas Tech Material Characterization Center (MCC) Instrument List

|

X-ray Diffractometer (MiniFlex 6G) Rigaku MiniFlex 6G X-ray diffractometer |

X-ray Diffractometer (SmartLab 3kW XE) Rigaku SmartLab 3kW XE X-ray diffractometer

|

Field Emission Scanning Electron Microscope (FE-SEM) Hitachi S-4700 field emission scanning electron microscope (FE-SEM) equipped with EDAX energy dispersive X-ray (EDX) spectrometer |

Transmission Electron Microscope (TEM) Hitachi H-9500 transmission electron microscope (TEM) equipped with EDAX energy dispersive X-ray (EDX) spectrometer |

|

Focused Ion & Electron Beam (FIB-SEM) System Hitachi NB5000 focused ion & electron beam (FIB-SEM) system equipped with EDAX energy dispersive X-ray (EDX) spectrometer |

X-ray Photoelectron Spectrometer (XPS) Physical Electronics PHI 5000 VersaProbe II Hybrid X-ray photoelectron spectrometer (XPS) |

Atomic Force Microscope (MFP-3D-SA AFM) Asylum Research MFP-3D-SA atomic force microscope (AFM) |

Atomic Force Microscope (Dimension Icon) Bruker Dimension Icon with ScanAsyst atomic force microscope (AFM) |

|

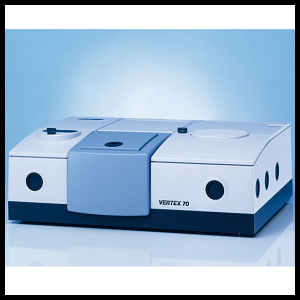

Fourier Transform Infrared (FTIR) Spectrometer/Infrared (IR) Microscope Bruker Optics VERTEX 70 Fourier transform infrared (FTIR) spectrometer HYPERION 2000 infrared (IR) microscope |

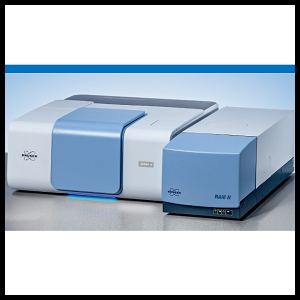

Bruker Optics RAM II FT-Raman spectrometer module RamanScope III FT-Raman microscope module SENTERRA dispersive Raman microscope spectrometer |

Spinning Disk Confocal System 3i Marianas spinning disk confocal system

|

UV-Vis-NIR Spectrophotometer Agilent/Varian Cary 5000 UV-Vis-NIR spectrophotometer

|

|

Thermogravimetric Analyzer (TGA) Mettler Toledo TGA/SDTA851e module thermogravimetric analyzer

|

Differential Scanning Calorimeter (DSC) Mettler Toledo DSC822e module differential scanning calorimeter

|

Particle Size Analyzer (Zetatrac) Microtrac Zetatrac Ultra particle size & zeta potential analyzer, particle size measuring range 0.8 nm-6.5 μm |

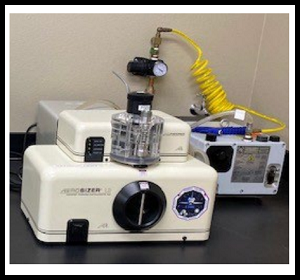

Particle Size Analyzer (API Aerosizer) TSI API Aerosizer particle size analyzer, particle size measuring range 0.2-700 μm |

|

Micropore Analyzer Quantachrome Autosorb iQ-MP micropore analyzer

|

Zeta Potential Analyzer Particle Metrix Stabino particle charge mapping system

|

Gas Chromatograph-Mass Spectrometer (GC-MS) Agilent 7820A gas chromatograph (GC)-5977B mass selective detector (MSD) system |

Sputter & Carbon Coater EMS Q150V ES Plus Sputter & Carbon Coater

|

Texas Tech College of Arts and Sciences Microscopy Instrument List

|

Zeiss Crssbeam540 Large are mapping, EDS mapping, EBSD mapping, FIB

|

Hitachi 7650 Transmission Electron Microscope Morphology, diffraction

|

Hitachi 4300 Scanning Electron Microscope Environmental SEM Cathodoluminescence

|

Texas Tech Geoscience Department Instrument List

|

Laser ablation ICP mass spectrometer highly sensitive elemental and isotopic analysis

|

X-ray Diffractometer Bruker phase identification of a crystalline material

|

Texas Tech Building 61 Laboratory Space

Our laboratory at building 61 sits on 10,000 square feet (i.e., actual building area per floor) with building height 48 feet and sprinkler system. The floor building exits, and corridor widths are 44 inches. Exit separations of 100 feet and the number of exits required and available are 2. The occupant load is 109 with corridor rating of 0 hour. The entire building has a security and alarm system service that is provided by Texas Homeland Security and Sound. The security system and motion sensor alert the local police if the building is intruded. More so, the local fire department is notified with the aid of GDS Corporation control and Firetrol protection systems that alert if smoke and fire outbreak occur in the laboratory. The bullet proof windows all around the building is an added safety feature which promotes a healthy and conducive work environment.

The main laboratory area is 30,000 square feet with two fume hoods and one emergency safety shower/eye wash station. In this area, we have two mass spectrometers, nitrogen fixation experiment station, near zero environment electrochemical set ups, SRS RGA 300 (Residual Gas Analyzer), Eppendorf centrifuge 5810, Bruker M1 0RA XRF (X-ray fluorescence) and nanoparticles development/synthesis station.

Calorimetry room is 600 square feet; it has a vacuum calorimeter, mass spectrometer and electrocatalytic experiment set ups. The wet chemistry room is the same size has the calorimetry room with a fume hood, Millipore deionized water system and Carbolite Gero furnace (30-1,200oC). Materials are etched and annealed in the furnace in this room. Chemicals (salts, reagents, acids, glassware's, and glovebox) are safely stored and prepared in the fume hood at this location.

Metallurgy works are conducted in the machine shop, which is 800 square feet for milling and fabricating materials. The second machine shop is 1,050 square feet used for orbital welding, rolling and room temperature air press for materials. The laser experiment room is 650 square feet and has a mass spectrometer. All these rooms have emergency safety electrical and fire extinguishers, shower/eye wash station, smoke detectors, oxygen, and hydrogen sensors.

The office area in building 61 is about 2,000 square feet for scientist's personal workspace and 200 square feet conference room for research group meetings. The break room is 300 square feet, and the building has a male and female restroom.

Texas Tech Machining, CNC Milling, and 3D Printing Capabilities

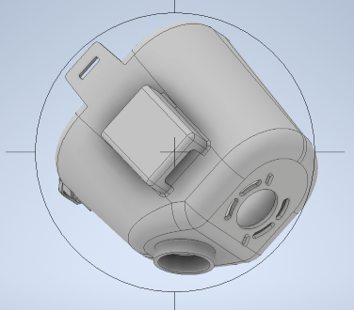

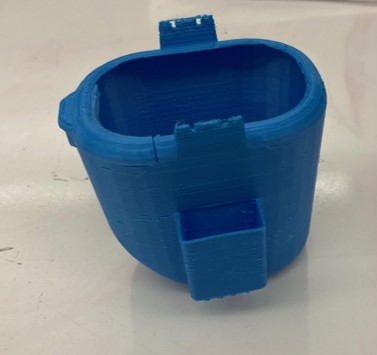

We provide access to top-quality components suitable for fast prototyping and low-volume industrial production through FDM 3D printing. Our FDM services cater to quick-turn manufacturing, utilizing a wide range of durable materials suitable for various applications. With our efficient processes, we can create printed parts within two days.

Manufacturing with FDM 3D printing: FDM 3D printing, also known as fused deposition modeling, is a process that creates custom parts by layering and extruding thermoplastics. This technology is ideal for both initial and functional prototyping, as well as low-volume production, offering a wide selection of robust plastic materials. Despite being a cost-effective solution, FDM goes beyond just small-scale manufacturing. When utilizing FDM, you gain access to a range of thermoplastics such as PLA, ABS, TPU, PETG, and PEI. Additionally, you can expect a dimensional accuracy of ±0.5% with a lower limit of ±0.5 mm (0.0196").

Manufacturing with Resin 3D printing: Resin 3D printing, commonly referred to as Stereolithography (SLA), is an advanced 3D printing technique renowned for its ability to create high-resolution parts with exceptional accuracy, intricate details, and smooth surface finishes. As a member of the vat photopolymerization printing family, SLA technology employs photosensitive thermoset polymers to produce customized components.

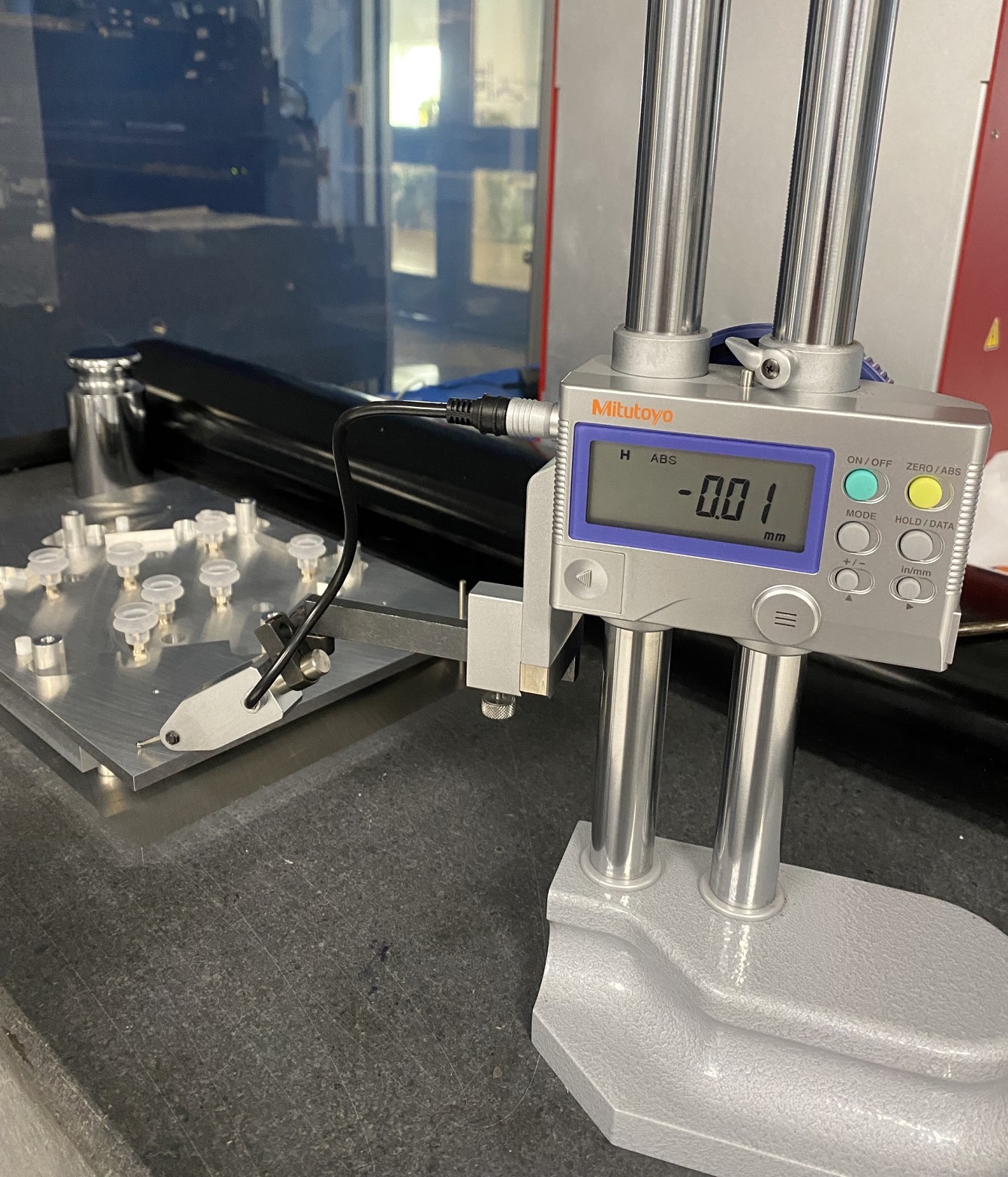

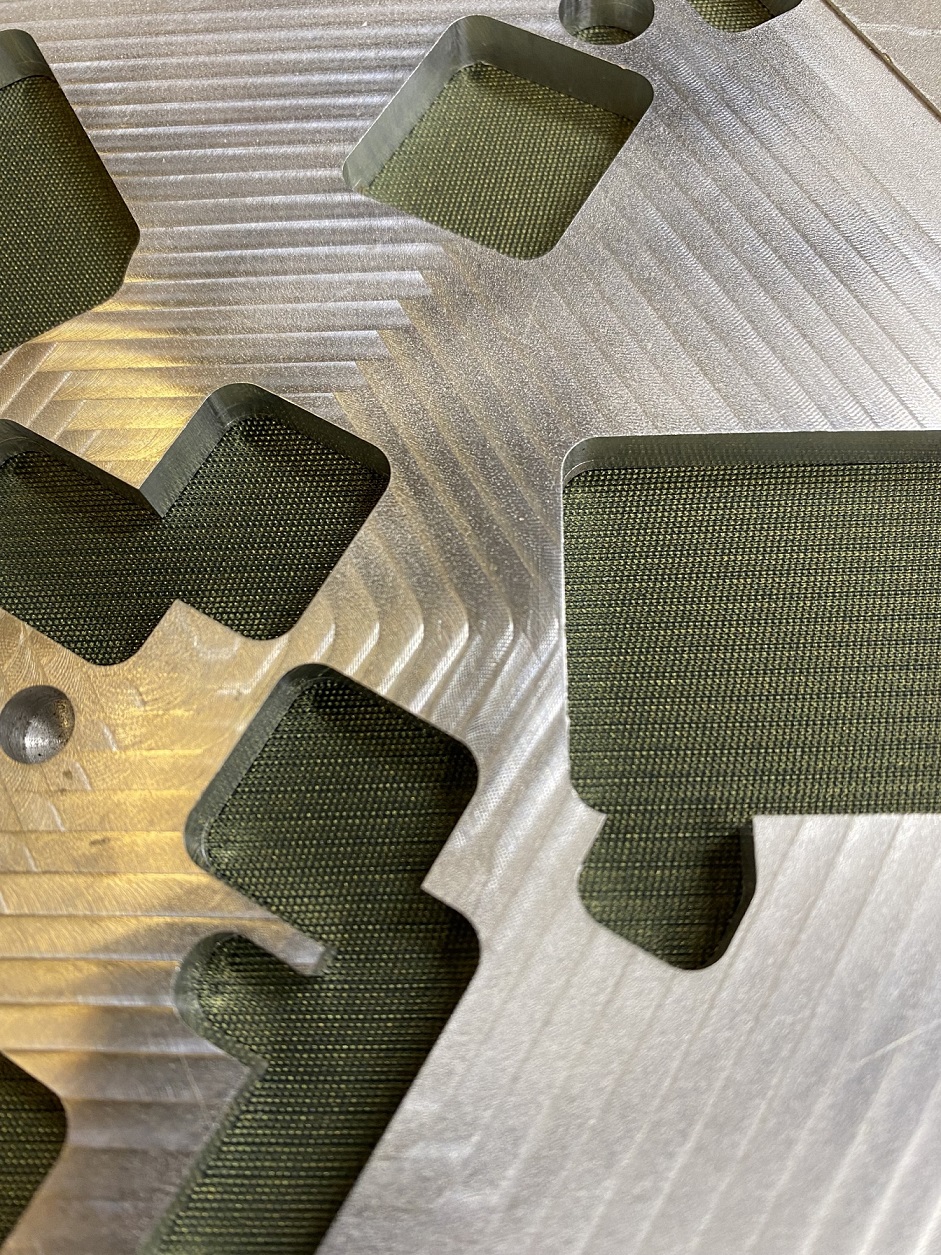

Manufacturing with CNC milling: CNC milling is a manufacturing process that utilizes rotating cutting tools to selectively remove material from a workpiece, resulting in the production of finished parts and products. This versatile technique is suitable for working with various materials such as metals, polymers, wood, and glass. CNC milling systems typically operate along three linear axes: the X, Y, and Z axis, providing exceptional precision and intricate detailing capabilities.

We provide orbital welding for tubing size range from 1/8” – 1/2” diameter. We invite you to Contact Us so that we may discuss your immediate requirements.

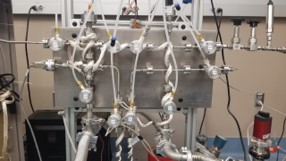

Swagelok Orbital Welding: The Swagelok M200 Orbital Welding System is a state-of-the-art unit utilizing a color touch screen, featuring a wide range of size and material capabilities, in addition to accessories which are customizable to your job requirements.

CEES Orbital Welding: We successfully developed a bellow valve system utilizing CF flanges through orbital welding. This system offers flexibility for replacement while providing significant advantages such as ultrahigh vacuum compatibility and the ability to undergo baking out processes. Compared to VCR fittings, it offers greater rigidity, and in terms of hermeticity, it surpasses Swagelok compressed fittings. To our knowledge, no other provider offers valves of this nature. Furthermore, these valves can be utilized in helium-leak-free manifolds as well.

Department of Physics and Astronomy

-

Address

Texas Tech University, Department of Physics & Astronomy, Box 41051, Lubbock, TX 79409-1051 -

Phone

806.742.3767 | Fax: 806.742.1182 -

Email

physics.astronomy.webmasters@ttu.edu | physics.academic.advising@ttu.edu