Rotary Evaporator Malfunction, Change of Routine Leads to Damaged Fume Hood

What Happened?

On March 2, 2021, a student was using a rotary evaporator (rotovap) to remove excess methanol from the synthesized product. The student secured the evaporating flask and started the equipment, closing the fume hood sash as they walked away to complete another task on an adjacent aisle.

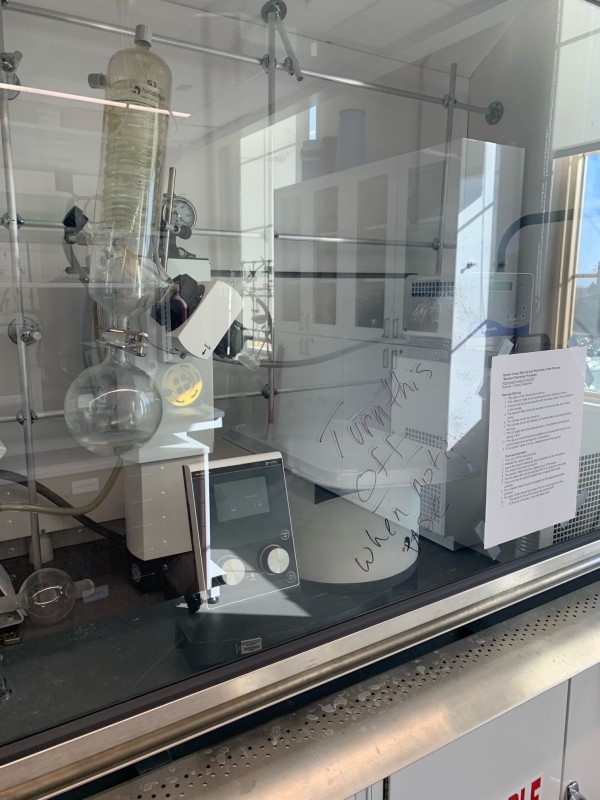

The student heard a loud "pop" from the fume hood and went to investigate. The evaporating flask (indicated by the red arrow in the image to the right) attached to the rotovap had exploded damaging the interior face of the fume hood sash. No personnel were injured during the incident.

What was the cause?

The laboratory group had just purchased a newer model rotovap to replace an

What went right?

The student had securely closed the fume hood sash which contained the flying glass debris and chemical mixture from the evaporating flask inside the fume hood.

What corrective actions were taken?

- A new Standard Operating Procedure (SOP) was written by the lab's Principle Investigator after consulting with manufacturer recommendations and other users of the same piece of equipment.

- The entire research group was retrained on the new SOP.

- The SOP was posted on the fume hood sash where the rotovap is used.

- A poster of temperature vs. pressure for common solvents was posted next to the fume hood as well.

How can we prevent incidents like this?

- Never assume that similar equipment will behave the same. Perform calibrations, review the manufacturer manual and establish expected parameters for use when replacing equipment or purchasing new equipment.

- All glassware should be inspected carefully before use with a rotovap and should not be used if it's visibly damaged. Aside from cracks, look out for any scratches or chips. Note that it only takes a tiny crack to compromise the integrity of the glassware and cause it to implode once under vacuum.

Environmental Health & Safety

-

Address

Texas Tech University, 407 Flint Ave, Lubbock, TX 79409 (Mail Stop 1090) -

Phone

806.742.3876 -

Email

safety@ttu.edu