Proactive Monitoring in Research Lab Prevents Incident During Carbon Monoxide Leak

What happened?

During a methanol synthesis reaction, carbon monoxide gas was released into the laboratory. The experimental setup has two main sections – the reaction site and the detection site. The reaction site is a methanol synthesis reactor and gas chromatography (GC) is used to detect and quantify the methanol product. Carbon monoxide (CO) gas leakage happened at the detection site. Consumer-type CO detectors employed in the lab indicated that concentrations reached 120 ppm. CO gas flow to the GC line was stopped immediately after the CO detector alarmed and the lab was evacuated. After a couple of minutes, the researchers returned to investigate the issue.

What caused the leak?

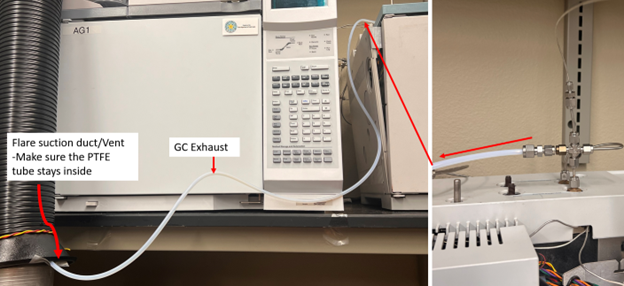

The setup is equipped with two CO detection alarms, one installed near the GC and one installed near the reactor. The GC and reactor exhausts are ported to a local ventilation duct using plastic tubing. Before running the experiments, the whole system was checked twice with inert gas to detect any leaks. The reaction and GC sites were found leak free.

The cause of this accident was the loose PTFE tube from the GC exhaust. This line was only pushed onto the fitting threads, and it was not secured with a Swagelok fitting. The GC exhaust was thought to be insignificant.

During tests, the PTFE tubing came off the fitting and the GC exhaust was released directly into the laboratory environment without being directed to the local ventilation duct. The CO detector alarmed at 120ppm. Gas flow to the GC line was shut off immediately after the CO detector started beeping.

What went right?

- Gas monitoring devices were employed, warning lab personnel of the problem.

- Local exhaust ventilation was in place to remove excess CO that had passed through the synthesis or detection processes.

- The lab had a procedure to shut down the reaction process safely in the event of a release and lab personnel were familiar with that procedure.

- The incident was promptly reported to EHS.

What corrective actions were taken?

After the incident, the vent line was replaced with new PTFE tubing and Swagelok fittings and affixed to the suction duct so that it could not come out easily.

What can still be improved?

- The laboratory personnel clearly understood the risk of working with carbon monoxide but underestimated the potential for CO to pass through both the synthesis and the detection processes. To gain a baseline knowledge of CO production, EHS will conduct air monitoring in collaboration with the lab personnel to determine the amount of CO that makes it through each process.

- Procedures for determining that the workspace is safe to return to need to be developed. Laboratory personnel only had the two consumer-type CO sensors to gauge the amount of CO left in the room.

Environmental Health & Safety

-

Address

Texas Tech University, 407 Flint Ave, Lubbock, TX 79409 (Mail Stop 1090) -

Phone

806.742.3876 -

Email

safety@ttu.edu